Characteristics of military aerospace products and the reflow welding process requirements: Due to its special requirements and application, the welding process and conventional welding processof military PCB is very differentthan others, require the solder jointto bemore reliable, and more durable, BGA components welding quality to be more solid, and for multi-layer PCB products wel...

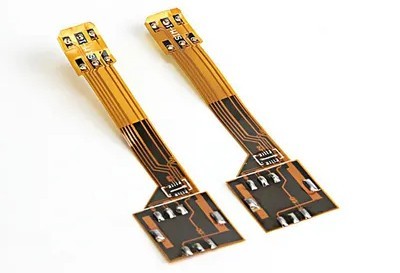

FPC flexible circuit board product characteristics and reflow welding process requirements: FPC flexible circuit board, also known as flexible board, is a conductor circuit pattern on a flexible substrate surface by using optical imaging image transfer and corrosion process methods. The surface layer and the inner layer of the double-sided and multi-layer circuit board realize the interna...

Mini LED pads have large and small sizes. There are usually thousands of chips and tens of thousands of solder joints on each Mini LED circuit board to connect RGB tri-color chips. The big welding spots on the product bring very great difficulty to the chip packaging welding, for big size products with number of welding spots, the reflow soldering temperature uniformity control, nitrogen and oxygen content control, and other aspects are especially important, otherwise it may cause some welding point virtual welding, surface black, welding spots off

In order to meet the high density, low void content, and miniaturization design requirements of the electronic products, the packaging welding quality is becoming more and more high, many electronics manufacturers require to semiconductor reflow oven, to make the solder paste printed on the convex metal surface to be reflowed into ball shape, and make the tin ball combined with the base board, and then the chip is joint to the integrated circuit boards, It is also needed to weld the chips and circuit boards together, so it is essential for chip packaging and the manufacturing of integrated circuits.