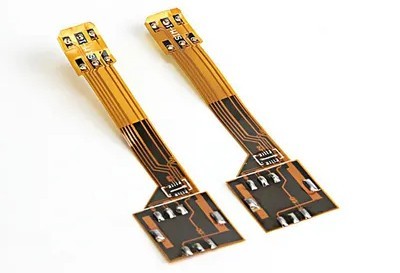

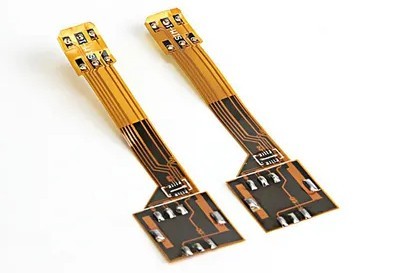

Case details

FPC flexible circuit board product characteristics and reflow welding process requirements:

FPC flexible circuit board, also known as flexible board, is a conductor circuit pattern on a flexible substrate surface by using optical imaging image transfer and corrosion process methods. The surface layer and the inner layer of the double-sided and multi-layer circuit board realize the internal and external electrical connection, through the metallization connection; the line graphic surface is protected and insulated by PI and glue. It is mainly divided into single side board, hollow board, double side board, multi board, soft and hard combination board. Its characteristics are: small size, light weight, flexible, bending, thin, which are widely used in precision small electronic equipment, and can be used to connect dynamic electronic parts.

Due to the characteristics of small size, light weight and thin thickness, FPC products have high requirements for hot air flow control, cooling air flow control, hot air temperature uniformity, nitrogen local protection, etc.

It is mainly used in mobile phones, laptops, scanning guns, digital cameras, tablet computers, LCD monitors and other products.

Reflow welding solution

According to the characteristics of FPC products such as small size, light weight and thin thickness, it is particularly important to ensure the uniformity of temperature control; nitrogen protection and air flow control for reflow welding. Otherwise, it may cause some bad phenomena such as false welding and welding spot offset, which cannot meet the requirements of welding process.

Suneast reflow oven has the following characteristics for FPC industry:

1. The heating and cooling zones are controlled independently by separate inverter, which can effectively control the air volume of each section, to ensure the uniformity of temperature, and meets the cooling slope requirement.

2. With nitrogen protection, prevent pad oxidation which will result in bad welding.

3. Double cooling zones, effectively control the cooling slope.

4. New flux recovery system, ensure flux recovery more thoroughly, keep the furnace clean, save maintenance time, reduce the cost of use.