Wave soldering is a global soldering technology. During the welding process, the entire PCB board is immersed in the molten solder, and the solder wave's impact force and wetting properties evenly coat the solder on the leads of the components that need to be welded. Itis suitable for mass production and high-density PCBboard welding, with high welding efficiency and able to meet the ...

Since its birth, the linear motor drive technology has become more and more mature. It is widely used in various fields due to its outstanding advantages such as high precision, no wear, low noise, high efficiency, fast response, and space saving. It is widely used in civil, industrial, military and other industries. For example, in the transportation industry, in the construction industry, in the semiconductor industry, and in the medical industry, linear motors are all indispensable automation equipment.

Precision dispenser is a kind of dispensing equipment with high precision in the automatic dispensing industry, which is generally used in the field of electronic communication, automobile manufacturing and LED and chip packaging. The dispensing range of precision dispensing machine is small and the dispensing amount is small, which needs high-precision control. It can realize automatic loading and unloading in the whole process without manual operation. In addition, its slideway and transmission operation mode is more flexible than the general dispensing machine. It extrudes the glue through air pressure, and controls the glue output by the dispensing valve. It can be used to accurately spot, inject, coat and spot the product to the exact position where the glue needs to be dispensing. It can be used to achieve dot, line drawing, circular or arc type, with higher dispensing accuracy. Precision dispenser has more advantages than ordinary dispenser in dispensing efficiency and precision.

The temperature setting of each temperature zone of reflow oven with 8 temperature zones is set according to the action principle of the temperature zones (preheating zone, constant temperature zone, reflow soldering zone and cooling zone) of reflow soldering. In fact, no matter with 8, 10 or even 12 temperature zones should follow this basic principle. Of course, we need to adjust it according to the actual situation of our production site, such as RTS or RSS profile? Different products are produced with different raw materials (PCB substrate material, thickness, material, mounting type, etc.), with different solder paste. the temperature settings is different.

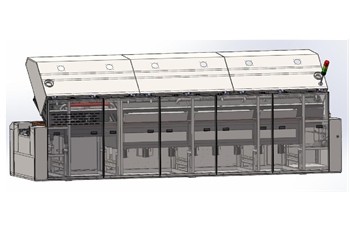

SER-7 series Reflow Oven Products Main Features