The snap curing oven adopts modular design and combines different functions,

like automatic temperature control, nitrogen protection, buffer cooling, automatic

loading and unloading and so forth. Through the specific temperature control,

atmosphere control and automatic operation, it can complete the process after

Die Attach equipment, which is mainly used in curing and bonding of semi-conductor packaging.

Core Technology:

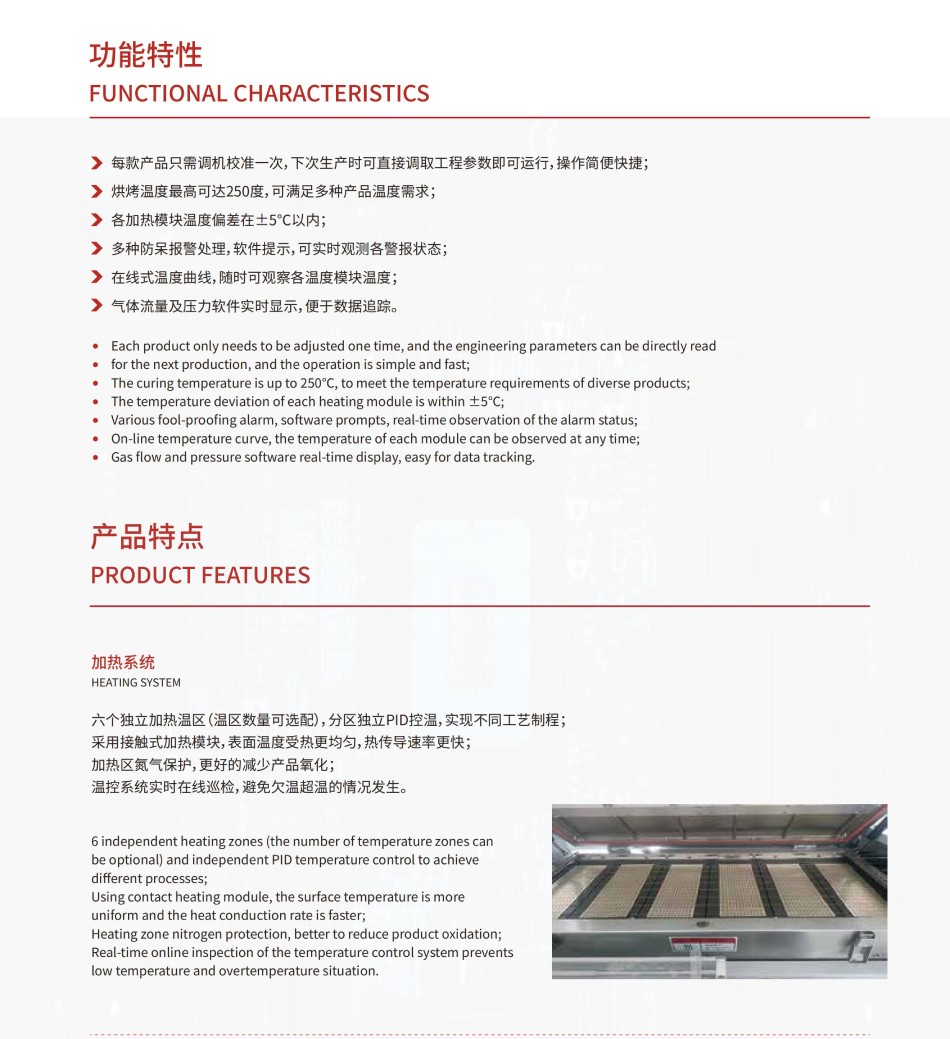

Heating system: with 6 zones,the temperature of each zone can be set separately; the lead frame is arranged in single row matrix for curing.

Conveyor system: Separate and independent conveying system, automatic control, with buffer section, and automatic collecting mechanism.

Control system: PC+PLC electrical control system, Windows operating interface, Chinese and English online free switching, LCD display, support remote monitoring.

Protection system: The machine has a variety of protection mechanisms, including over temperature protection, three-color light, buzzer fault alarm and software interface fault prompt.

Nitrogen system: Configure the flow meter to adjust the flow into the box and monitor the nitrogen consumption.

Functional Characteristics:

Each product only needs to be adjusted one time, and the engineering parameters can be directly read;

for the next production, and the operation is simple and fast;

The curing temperature is up to 250℃,to meet the temperature requirements of diverse products;

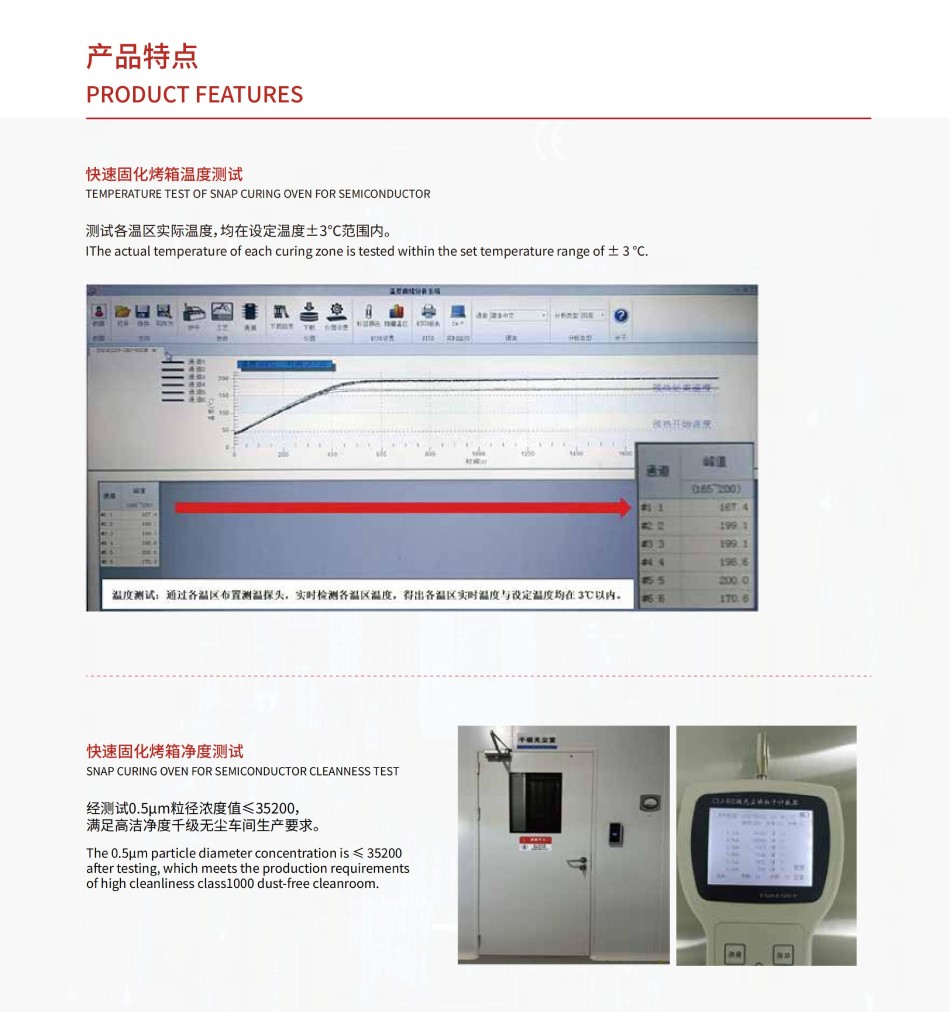

The temperature deviation of each heating module is within ±5℃;

Various fool-proofing alarm, software prompts, real-time observation of the alarm status;

On-line temperature curve, the temperature of each module can be observed at anytime;

Gas flow and pressure software real-time display, easy for data tracking.

| Model No | SEO-600N |

| Box part | |

| Lead frame size | L:125mm~300mm;W:25mm~100mm;T:0.12mm~1mm |

| Magazine size | L:130mm~308mm;W:30mm~110mm;H:100mm~180mm |

| Lead frame type | single row/matrix |

| Number of curing zones | 6(Optional) |

| Temperature setting range | 50℃~250℃ |

| Temperature uniformity | 士5℃ |

| Temperature controller | PID intelligent temperature control,SSR output control |

| Curing time | Set according to process requirements (The time can be set) |

| Nitrogen system | With N2 flowmeter interface,the nitrogen flow is adjustable. |

| Safety device | Overtemperature alarm device,earth leakage circuit breaker,overheat protection |

| Exhaust system | Independent interface with exhaust device |

| Nitrogen consumption | ≤100L/min |

| Compressed air and flow | 4-7bar,90L/min |

| Power supply | 三相380V AC 50/60Hz 3 Phase 380V AC50/60Hz |

| Startup power | 约3.3KW Approx.3.3KW |