2019-09-26

SER-7 series Reflow Oven Products Main Features

■Moduli zat ion Design

Two high performance modules have passed the national patent

Heating Module Cooling System Fluxer Recovery System Conveyor System

■ Humani zati on Desi gn

PC+PLC control, ensure the equipment to run stable; built-in welding Defection analysis, built-in equipment maintenance manual; etc.

■Low-cost running Design

Fluxer management system; extend the maintenance interval time of the furnace chamber; convenient, efficient and maintainable design concept; effectively cut down the maintenance time; non- stopped fluxer management system and cooling system; forced air cooling system to reduce the running consumption of the cooling chiller etc.

■Energy-savi ng and Environment-protecti ve design

Part 1:Modulization structure introduction

1.Heating Module

1.Heating Module(Sun East Patent structure design, Patent number: 201721160420.1)

Feature: Efficient heating module, Front and rear air circulation, better temperature uniformity, high heat efficiency

High temperature motor: it can be convenient for maintenance and replacement (air wheel / heating pipe)

Heat pipe: can change different power

2. (Cooling system )

Feature:

①Satisfy lead-free welding quick-cooling requirement

②Prevent the components and PCB from bending

③Easy and efficient to maintenance.

④Strong cooling system expandability( the air cooling can be upgraded to be water cooling)

3. Fluxer Recovery system

Feature:

①Multi-level fluxer filtering to ensure high-activity processing

②Easy and efficient to maintenance without tools

③No need to turn off the machine to maintain ( on-line maintenance)

4. Conveyor system(High reliability, rail deformation prevention design)

Feature:

①The rails is adopting special aluminum alloy and doing superhard and oxidation treatment insurface( anti-distortion , anti-wear )

②The rails is adopting two section structure design to enhance the bending resistance of the rail, anti distortion.)

③Special width adjustment and conveyor structure design to ensure PCB conveying stable and reliable.

④Manual + electrical width adjustment structure design

⑤Equipped with emergency manual conveyor structure to prevent PCB burned when the power is off.

5. Control system

• Electric: PC+ PLC control to ensure the equipment running stable

• Software

Ø Windows operation interface, support 2000/XP/win7 operation system

Ø Chinese-English & Traditional - Simplified switch operation is easy.

Ø Friendly interface

Ø Perfect temperature profile analysis, storage and invoking function

Ø Operator registered password , operating records

Ø The running parameter Digitization dynamic display

Ø Built-in welding defect analysis

Ø Built-in equipment maintenance manual

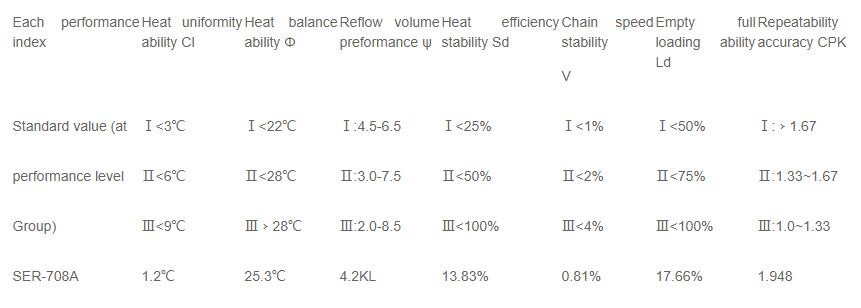

Performance Summery(SER-708A Reflow Oven)

Heat Efficiency Uniformity

▇If the uniformity is not good that means the crosswise risk is high, the profile which is tested by temperature test board can not reflect the real temperature of the same components on the product and the test points components. If doing the uniformity test on aluminum board which have strong thermal conductivity, it can not prove the precision and factuality of the test result, because its high inner heat conduction.

▇If the uniformity of the cooling zone temperature is not good, it will influence the total welding time of the product, the temperature dropping slope, solder crystallization effect, and the reliability of the product.

Heat Efficiency Balance

▇Larger differences in the degree of heat efficiency

⑴For different heat capacity components, like QFP and Socket, the temperature difference will be bigger during welding, and will make the debugging difficult and is even impossible to meet the temperature profiles requirements setting.

⑵The CPK will be bigger during processing.

⑶The alloy structure difference will be bigger. Reflow volume

▇Reflow ovens use hot air convection method to heat products, the strength of the reflow degree will directly affect the welding quality. Only the right fully reflow volume can obtain good welding quality.

▇If the reflow volume is too big, it will result in defect, like position deviation, upright parts, missing parts, short-circuit, non-wetting etc.

▇If the reflow volume is too small, it will lead to lack of convection, the reflow oven bad instability, poor thermal load capacity, poor CPK during processing.

Heat efficiency stability

▇The test results can help to quickly locate the reflow oven performance problems, enhance the detection analysis and maintenance efficiency, if the stability is low, then the actual temperature of the product during the welding process will be quite different, and the temperature profile was not representative, may lead to a variety of related serious quality problems.

Empty full-loading Heat compensation Ability Analysis

▇The reflow oven with strong empty full-loading heat compensation ability can adapt to the production with different sizes products, and various productivity. If the empty full loading capacity is insufficient, then the reflow oven loading capacity will be lower, and easy to cause serious harmful quality status, like cold welding etc.