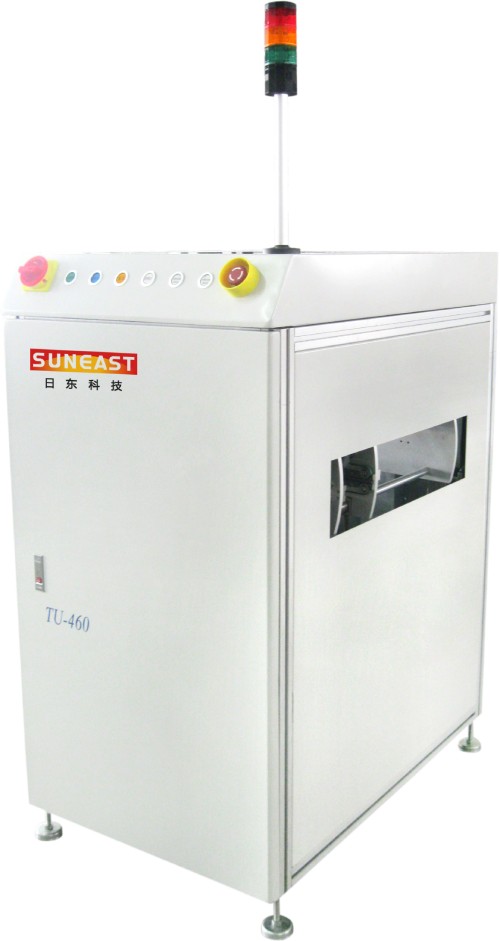

•Perfect solution for large size product printing

•Simple calibration and maintenance

•Stable printing quality

•Independent developed image processing software

Applicatelinear motor - high speed and high precision

The printing leader of 03015 micro component

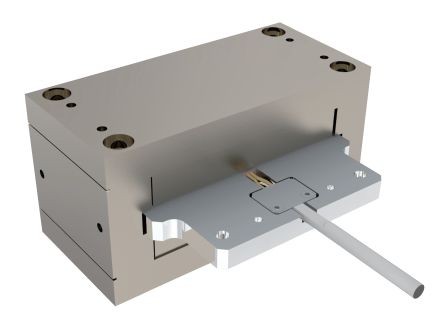

New mechanical design-more stable and convenient

New printing head design-high printing quality

The Ironless linear motor of Suneast technology won widely recognization with its mature technology and advanced design, which has been successfully applicated in visual detection, automatic installation, die bond, tablet , intelligent mobile phone and other semiconductor devices.

The most popular Ironcore motor SUNEAST TECHNOLOGY has to offer.In the machine design of high efficiency, high acceleration, micron accuracy, high-end iron core motor is good performances.The iron core motor suited for nearly any application, including Industrial robot, XYT axial table, gantry structure and CNC ect.

The high-end Voice Coil motors are available in various configurations that can easily be adapted to application sepcific requirements. Many Motors are successfully appliced throughout the semiconductor, for example Optical inspection,Auto assembly,die bonded,flatpanel and smart mobilephone.

It features small size high thrust, high efficiency, easy installation, many motor are successfully solution of the application of compact design indispensable.

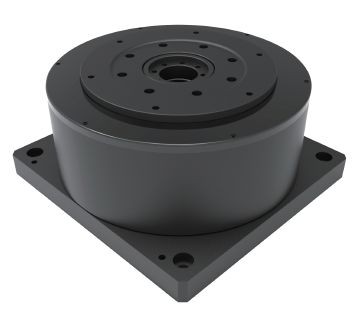

Suneast technology mastered the development of direct drive technology, and today offers the broadest range of direct-drivemaintenance, free clean mechanical assembly. improved accuracy, higher throughput, better reliability, and smooth, quiet operation to suit a wide variety of machine design needs.

Sun east technology provide development and produc ion of linear motor platform, It's including Iron Core series, Coreless series, Voice coil series and Rod series in application of linear motor platform.Those module product is often more effective to use in some precision module, such as application invision inspection, optical adjustment, Laser manufacture, Mark inspection, manufacture handling of industry, CNC, Semiconductor machine ect.These modules are equipped with optical encoder or magnetic encoder, non-contact position encoder.It has the characteristics of reliablity, stability, fast response and high accuracy, ect.It can realize fast and flexible driving control of single axis movement, multi-axis and gantry control.In application, the maintenance is convenient and the service life is long.In dimension mounting, the compact strut u redesign saves installation space and is easy to extend.

The Chip Bonder is used for multi-chip placement, with mature technology application platform, which offffers higher accuracy with new camera system and thermal compensation algorithm, and higher speed through a new image processing unit and architecture.

General type high-precision IC bonding machine, which is suitable for mass wafer loading products, SIP packaging, Memory Stack Die (memory stack), CMOS, MEMS and other processes.

Heavyduty industrial chain+rail conveyor, suitable for high load, with less running wear,long service life, more stable and reliable.

The carrier(fixture) can be different designed, flexible, to meet a variety of complicatedloading and unloading process.

1. The solder paste which is printed on the convex metal surface will be refluxed into a ball to complete the combination welding of the tin ball and the substrate.

2. After the chip is placed to the PCB, the chip and the circuit board are connected together to realize the chip packaging and integrated circuit manufacturing.

Integrated spray/preheat/welding function;

Independently developed electromagnetic pump, stable wave;

Compact design, small footprint、energy saving,Quick Changeover;

Real time monitoring and recording of welding process.

Special use type high precision IC bonder, for a variety of small batch of placement products. It can automatically switch to a variety of bonding heads, and quickly realize the placement of different parameters of a variety of chips.

Bare board vacuum loader:Flexible high pressure suction cup, suction position adjustable;For mass PCB, can be served as direct conveyor, and width adjustable.