Mini-led has smaller pads, less solder paste and smaller chips. It has higher requirements for the welding equipment cleanliness, temperature uniformity and other process parameters, and needs special MINI series high-end hot air welding equipment. The aero-engine turbine blade and eddy current technology hot air system and nitrogen heating technology are adopted, to ensure high quality and stability of the welding and meet the high requirements of MINI welding in the industry.

Features:

1. Efficient thermal compensation capability, customized hot air system to achieve the best thermal balance.

2. Multi-frequency converter control, fine temperature control, to achieve smaller welding spot temperature deviation.

3. New and upgraded flux recovery system, multi-stage filtration recovery, fully improve the recovery efficiency.

4. With nitrogen protection in the whole process, independent nitrogen control in each temperature zone, multi-point monitoring, the oxygen content will be within 200-500PPM.

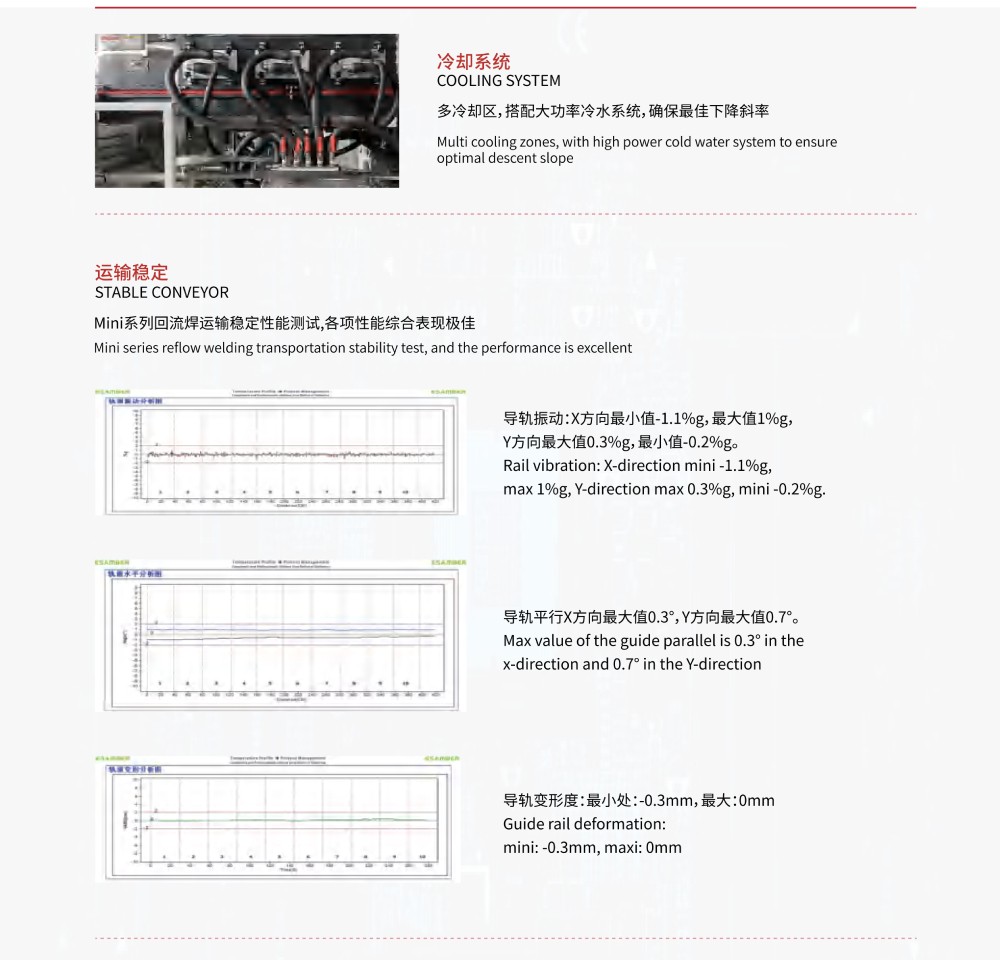

5. Multi-cooling zones structure, with high power cooling system, improve cold and heat exchange capacity, to meet the cooling slope requirements of each process;

6. Super wear-resistant high stable special rail system, auto cleaning, to meet the furnace cleanliness requirements, and ensure product welding quality;

| Model No | MINI-10N | MINI-12N | MINI-10DN | MINI-12DN |

| Heati ng system | ||||

| Heating zone structure |

10温区,20加热模块 10 heating zones, 20 heating modules |

12温区,24加热模块 12 heating zones, 24 heating modules |

10温区,20加热模块 10 heating zones, 20 heating modules |

12温区,24加热模块 12 heating zones, 24 heating modules |

| Heating zone length | 3670mm | 4390mm | 3670mm | 4390mm |

| Heating up time | 25min | 25min | 25min | 25min |

| Outlet Exhaust Diameter,valume | 2-Φ145,Exhaust demand 10m³/min x2 | |||

| Cooling system | ||||

| Cooling type | Three cooling zones:forced water cooling | |||

| Cooling zone length | 1250mm | |||

| Chiller power | 5P Water chiller | |||

| Conveyor system | ||||

| Conveyor Type | Chain+ mesh belt synchronous transmission | |||

| Conveyer Direction | L→R,R→L | |||

| Converyer Height | 900±20mm | |||

| Cmponent Height | Clearance above 30mm,Clearance below 20mm | |||

| Conveyor Speed | 300mm-2000mm/min | |||

| Guide rail structure | Dust free special hardened guide rail | |||

| PCB Width | Min50mm-max400mm (Option: max510mm) |

min50mm-max250mm(Dual tracks) min50mm-max450mm(Single track) |

||

| Fixed Rail Mode | Front rail Fixed(Option:Rear Rail Fixed) |

The front and rear guide rails are fixed, and the middle two guide rails can be movable. |

||

| Control system | ||||

| Power AC3Ø 5W 380V 50/60HZ | ||||

| Total Power | 96KW | 117KW | 96KW | 117KW |

| Startup Power | 38KW | 42KW | 38KW | 42KW |

| Normal consumption | 10KW | 12KW | 11KW | 13KW |

| Temp Control Range | Room temperature to 320℃ | |||

| Control type | PC+PLC Control system | |||

| Temp Control accuracy | ±1℃ | ±1℃ | ||

| PCB Temp Deviation | ±1℃ | ±2℃ | ||

| Data Storage | Process Data and status stotage | |||

| Power Outage Protection | Equipped with UPS | |||

| Operation Interface | Windows Chinese simplified, English online free switching | |||

| N2 area | Full nitrogen filling | |||

| MES communication protocol | Standard | |||

| Computer | Commercial computer | |||

| General | ||||

| Dimension(LxWxH) | 6400x1580x1650mm | 7120x1580x1650mm | 6400*1710*1650mm | 7120*1710*1650mm |

| Weight | 2500-2700kg | 3000-3200kg | 2900-3100kg | 3500-3700kg |

| Flux recovery system | Standard | |||

| Color | Bright wrinkled white | |||