The semiconductor oven with nitrogen filled has strong universality, high stability and high performance. It adopts high capacity horizontal air recycling system, adopts special chamber structure and sealing technology, with excellent air tightness and temperature uniformity to meet the high performance requirements of semiconductor products. This oven is suitable for curing semiconductor wafers, IC packages (copper substrate, silver gel, silica gel, epoxy resin), glass substrate and other products.

Features:

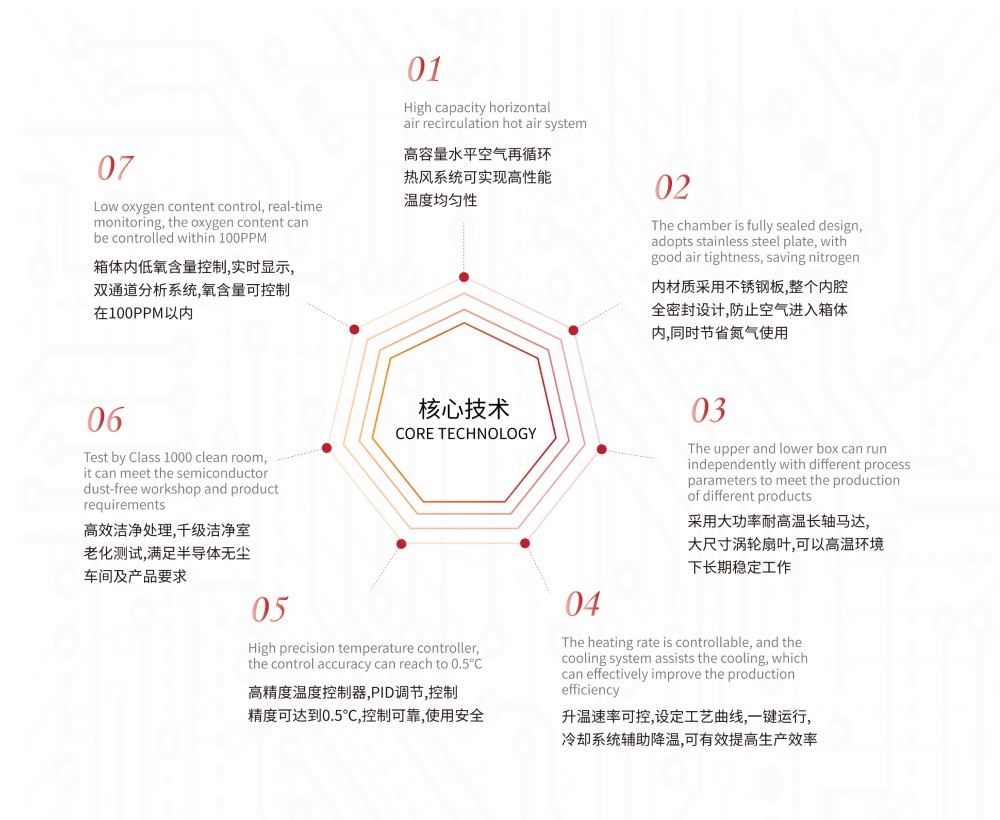

1. High capacity horizontal air recirculation hot air system

2. The chamber is fully sealed design, adopts stainless steel plate, with good air tightness, saving nitrogen

3. The upper and lower box can run independently with different process parameters to meet the production of different products

4. The heating rate is controllable, and the cooling system assists the cooling, which can effectively improve the production efficiency

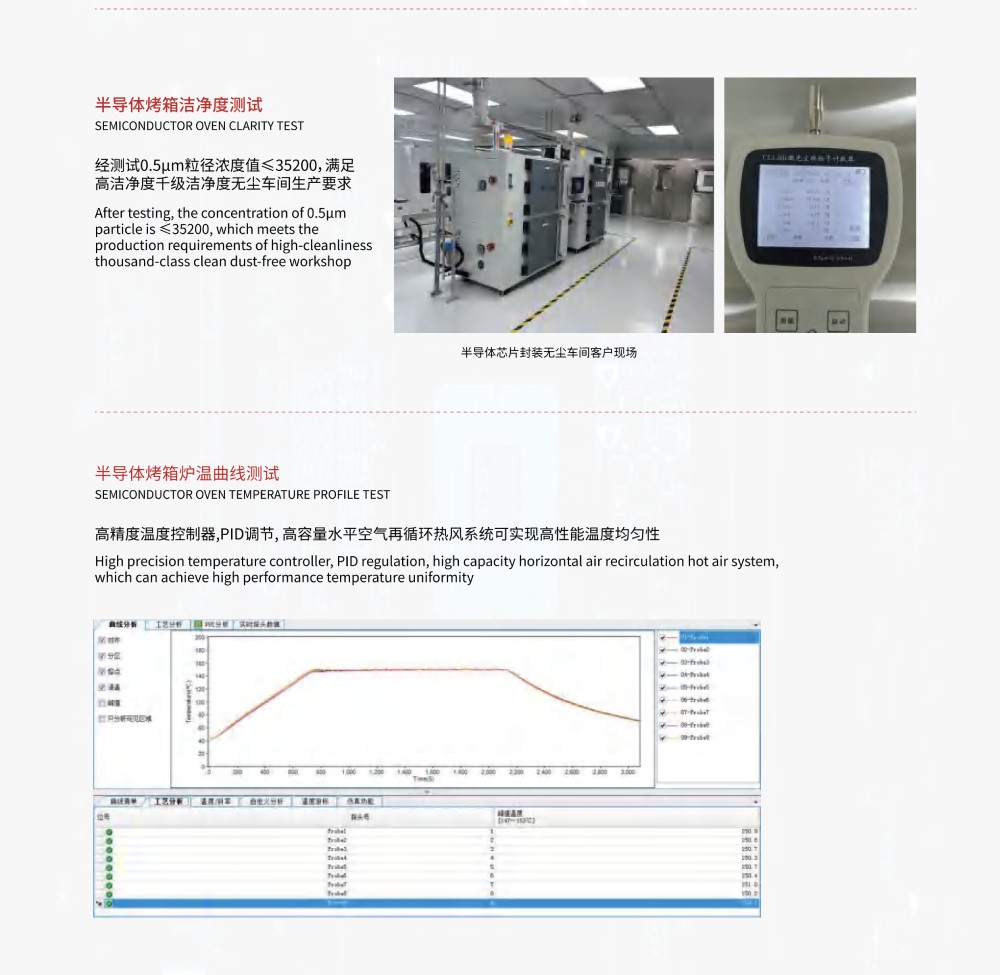

5. High precision temperature controller, the control accuracy can reach to 0.5℃

6. Test by Class 1000 clean room, it can meet the semiconductor dust-free workshop and product requirements

7. Low oxygen content control, real-time monitoring, the oxygen content can be controlled within 100PPM

| Model No | SEO-100N |

| Heating system | |

| Box dimension | L700*W550*H(600*2)mm |

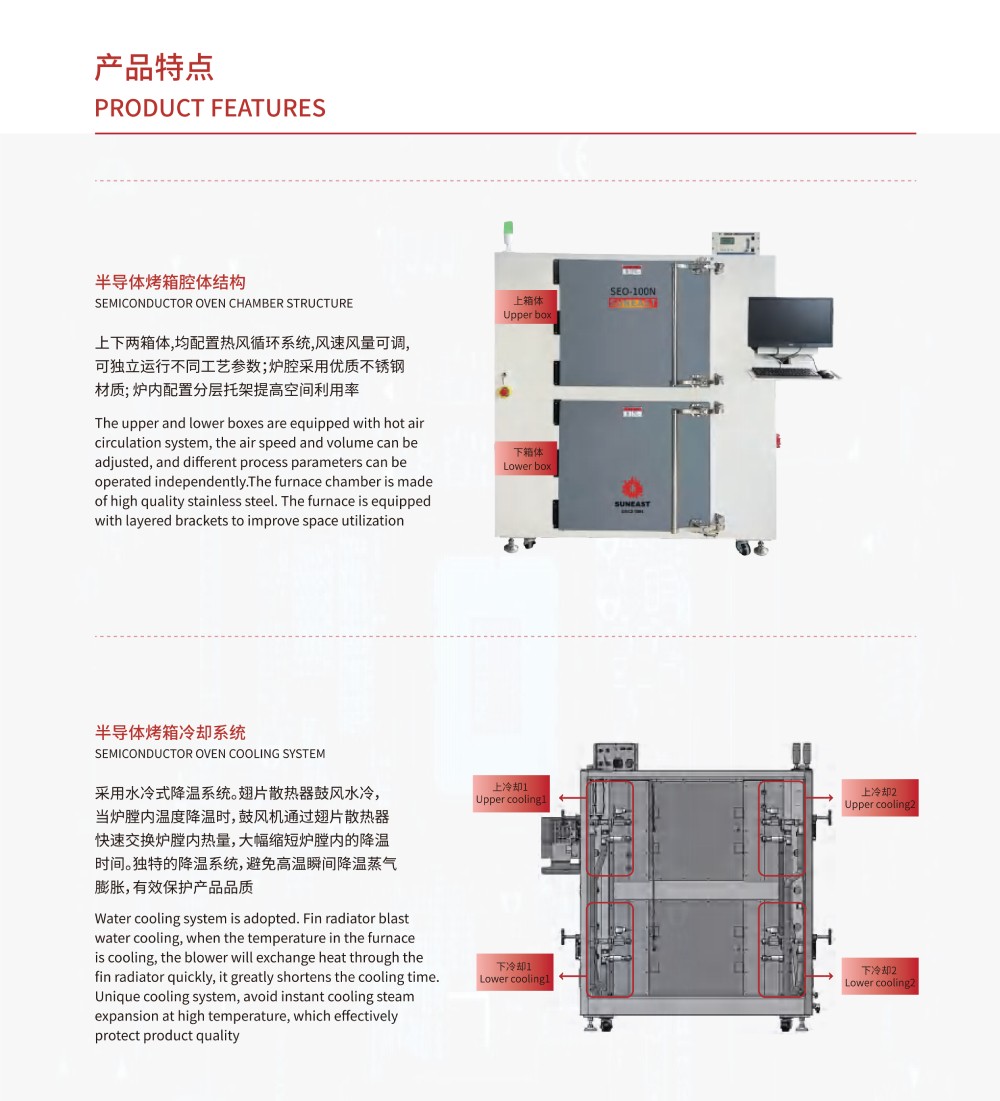

| Number of boxes and working mode | Two boxes, each box can run independently |

| Hot air system | Hot air circulation system with adjustable wind speed and volume |

| Cooling system | Water cooling circulation system, according to customer workshop cooling water |

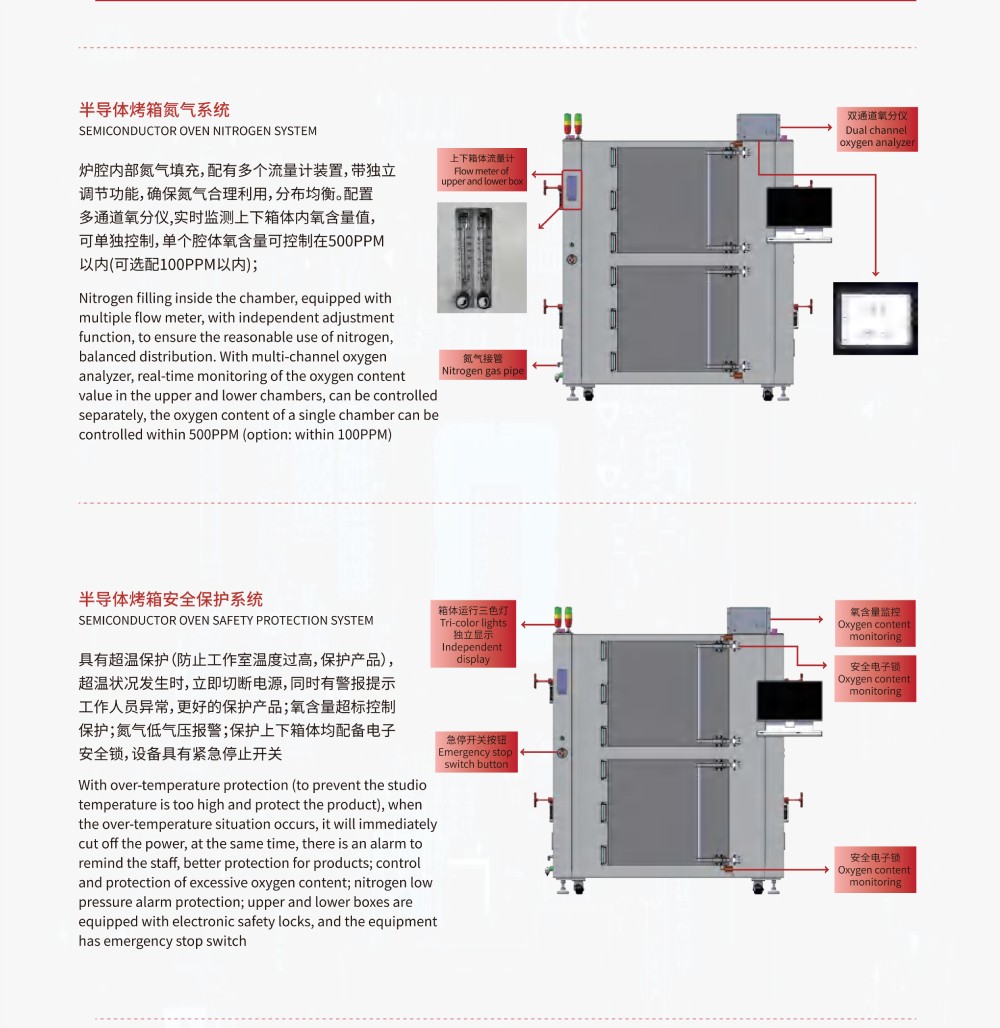

| Nitrogen system | With flow meter and oxygen analyzer to display oxygen content in real-time |

| Internal specification | Equipped with 4 stainless steel support shelves, with adjustable spacing between shelves |

| Cooling system | |

| Temperature operating range | Room temperature+10℃~250℃ |

| Temperature control mode | PID closed-loop control+SSR drive |

| Control system | PC+PLC electrical control system, Windows operating interface |

| Temperature accuracy | ±0.5℃ |

| Temperature uniformity | ±2%℃(no- load) |

| Heating rate | ≥5℃/min |

| Cooling rate | 2-5℃/min |

| Heating power | 10KW*2 |

| Oxygen content control | ≤500PPM(Option:≤100PPM) |

| Working voltage | AC3Ø 5W 380V50/60HZ |

| Total power | 21KW |

| MES communication protocol | Standard |

| Cleanliness class | Class 1000 |

| Conveyor system | |

| Dimension(LxWxH) | L1700*W1200*H1800mm |

| Weight | 500-800kg |

| Color | Bright wrinkled white |

| Remark:Support to customize the nitrogen or vacuum oven | |