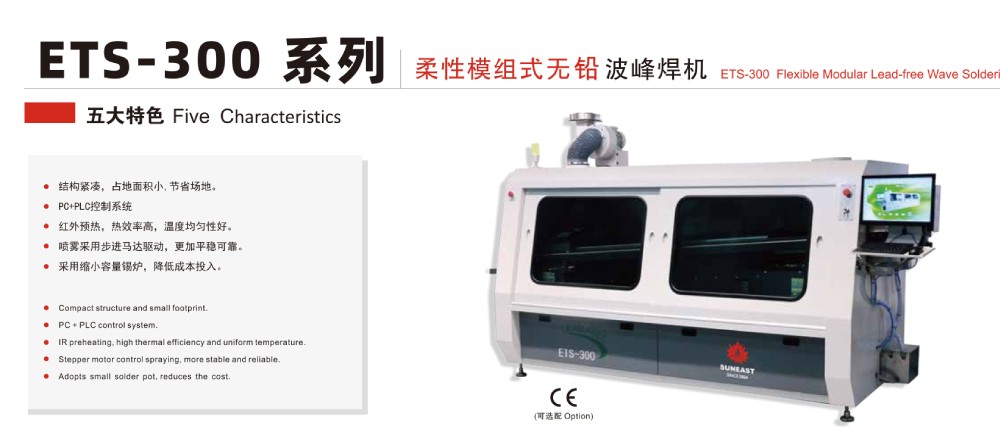

Compact structure and small footprint.

PC+PLC control system.

IR preheating, high thermal efficiency and uniform temperature.

Step motor control spraying, more stable and reliable.

Adopts small solder pot, reduces the cost.

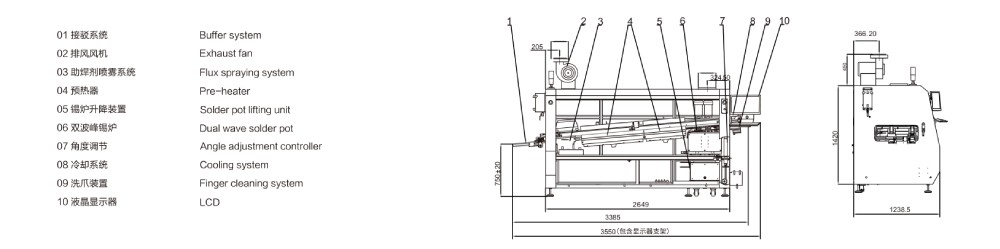

●Transportation:Input board directly.Stainless steel chain conveyor, durable and special design for aluminum alloy track.Applied floating track for different

stages for preventing deformation.

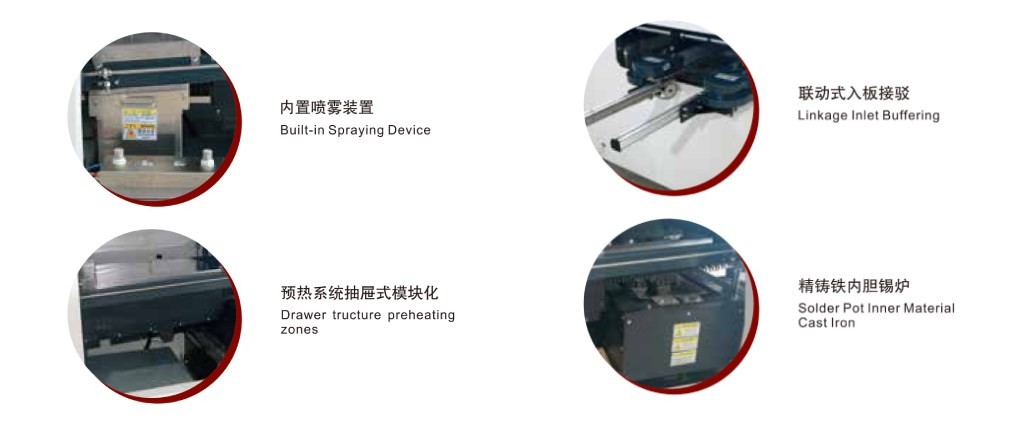

●Preheatingsystem:Drawer-typeenergy-savingdesign, IR preheating, PID mode temperature control, temperature control accuracy can reach±2℃, the

temperature dropping is≤5℃between preheating zone and soldering zone

●Flux spraying system:Managed by digital control.The motion of the spray nozzle is controlled by stepper motor.Flux supply is controlled automatically

for optimized effect.Exhausting and filter system installed on the top

●The solder pot is made by cast iron with anti-corrosion ceramic coating equipped with two low flowrate nozzles.

●Forced air cooling system.

●PC+PLC control system, Windows 7 operatingsystem, Chinese/English operation interface, process profile/data automatic storage function, lower or higher flux level alarm; lower tin level alarm.

| Modol NO | ETS-300 | ETS-300E |

| Dimension:LxWxH(mm) | 3385x1240x1540 | 3385x1190x1540 |

| Weigh | Approx.1150kg | Approx.1100kg |

| Power Supply | 3PH 380V 50HZ | 3PH 380V 50HZ |

| Startup Power | 28KW | 27KW |

| Operation Powr Consumption | 7KW | 6.7KW |

| Control System | PC+PLC | PC+PLC |

| Spraying movement | Step motor | Step motor |

| Spray Pressure | 0.2Mpa~0.4Mpa | 0.2Mpa~0.4Mpa |

| Flux Flow Arrange | option | option |

| Auto Fill Flux | Standard | Standard |

| Exhaust | Top exhaust | / |

| ExhaustDucting Diameter(mm) | Φ250 | Φ250 |

| Exhaust tan power | 370W | / |

| Preheating Mode | IR | IR |

| Control Mode | PID | PID |

| Preheating Zone Number | 2 | 2 |

| Preheating Length(mm) | 1500mm | 1500mm |

| Preheating Temperature | Room temperature~200℃ | Room temperature~200℃ |

| Warm-upTime(min) | Approx.12min(seting:150℃) | Approx.12min(seting:150℃) |

| PCB Width(mm) | 50~300 | 50~300 |

| Convoyor Direction | L→R(Option:R→L) | L→R(Option:R→L) |

| Conveyor Speed(mm/min) | 500~1800 | 500~1800 |

| Conveyor Height(mm) | 750±20 | 750±20 |

| Available Component Heigh (mm) | Top120,Bottom15 | Top120,Bottom15 |

| Conveyor Speed Control Mode | Closed loop stepless speed regulationg Inverter | Closed loop stepless speed regulationg Inverter |

| Fingers | 1.Heavy type double hook finge 2.Light double hook finger(Option) | 1.Heavy type double hook finge 2.Light double hook finger(Option) |

| Conveyor Angle | 4~6° | 4~6° |

| Type of solder Pot | Motor drive | Motor drive |

| Solder Pot Material | Casting Iron | Casting Iron |

| Wave Height Adjustment | Digital Control by PC | Digital Control by PC |

| Cooling Method | Air cooling | / |

| Heater Power | 9KW | 220V9KW |

| Solder Pot Temperature | 300°C | 300°℃ |

| Solder Pot Capacity | Approx.350KG | Approx.350KG |

| Wave Drive Power | 180W*2 3PH 220VAC | 180W*2 3PH 220VAC |

| Solder Pot Warm-up Time | Approx.150min(setting:250C) | Approx.150min(setting:250℃) |

| Temperature Control Mode | PID | PID |

| Finger Cleaning System | Brush | / |