1、Conveyor system:Structure with anti-wearing material for longer lifetime.

2、Preheating system: Optimized hot air circulation, the temperature is more stable and even.

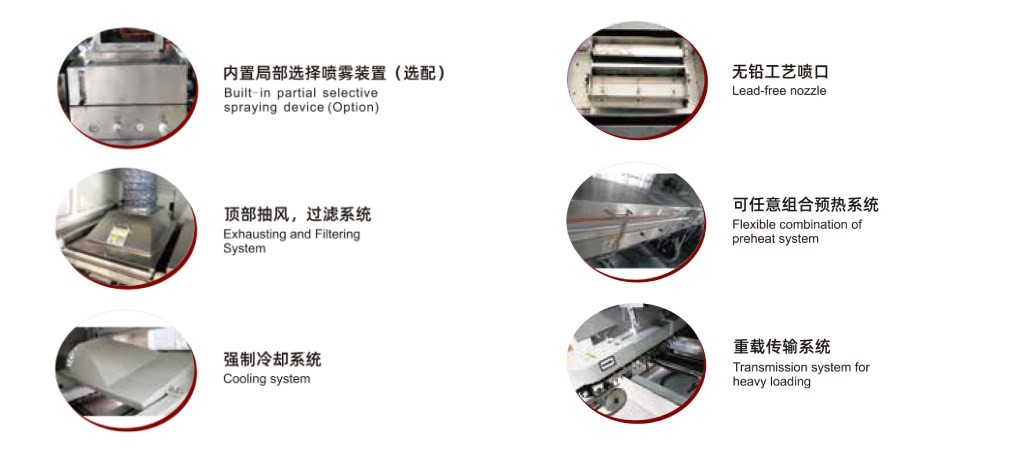

3、Exhausting system:Adopt new concept, seperate design, easy for maintenance.

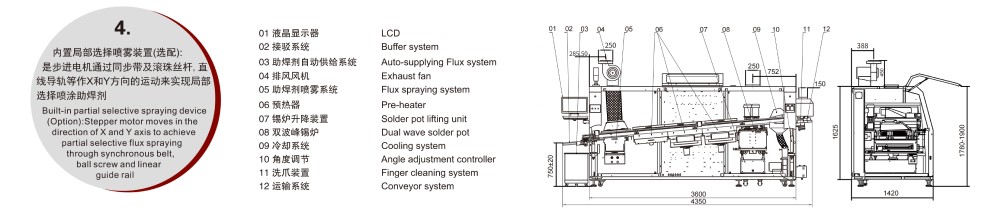

4、Built-in selective spraying unit(option): through synchronous belt, ball screw, linear guide rail for X and Y direction movement, the step motor will achieve local selection for spraying flux.

●Conveyor:Direct buffering input structure.Stainless steel chain conveyor, durable and special design for aluminum alloy track Adopt segment floating structure to prevent from deformation

●Pre-heatingzones:Designforenergysavingandremovablemodules(drawerdesign).Anycombinationofinfraredandhotairconvection.Use PID control to achieve±2℃accuracy.The temperature variation for pre-heating zone and soldering zone is less than≤5℃

●Flux spraying system:Managed by digital control.The motion of the spray nozzle is controlled by stepper motor Flux supply is controlled automatically for optimized effect.Exhausting and filter system installed on the top

●The solder pot is made by cast iron with anti-corrosion ceramic coating equipped with two low flowrate nozzles

●Aircoolingsystem:coolingrate4-6C/s(adjustable)

●PC+PLC control system.Windows 7 operation system with Chinese/English operation interface.Processing profile and data auto saving function Alarm for detecting the flux and solder level

| Modol NO | E-FLOW | E-FLOW-450 | E-FLOW-610 |

| Dimension:LxWxH(mm) | 4350x1420x1750 | 4350*1520*1750 | 4350x1690x1750 |

| Weigh | Approx.1600kg | Approx.1750kg | Approx.1950kg |

| Power Supply | 3PH 380V 50HZ | 3PH 380V 50HZ | 3PH 380V 50HZ |

| Startup Power | 33KW | 33KW | 45KW |

| Operation Powr Consumption | Approx.8KW | Approx.8.5KW | Approx.11KW |

| Control System | PC+PLC | PC+PLC | PC+PLC |

| Spraying movement | Step motor | Step motor | Step motor |

| Spray Pressure | 0.2Mpa-0.4Mpa | 0.2Mpa-0.4Mpa | 0.2Mpa-0.4Mpa |

| Flux Flow Arrange | Option | Option | Option |

| Auto Fill Flux | Standard | Standard | Standard |

| Exhaust | Top exhaust | Top exhaust | Top exhaust |

| ExhaustDucting Diameter(mm) | Φ250 | Φ250 | Φ250 |

| 抽风机功率Exhaust tan power | 750W | 750W | 750W |

| Preheating Mode | Convection / IR emitter | Convection / IR emitter | Convection / IR emitter |

| Control Mode | PID | PID | PID |

| Preheating Zone Number | 3 | 3 | |

| Preheating Length(mm) | 1800 | 1800 | 1800 |

| Preheating Temperature | Room temperature~200℃ | Room temperature~200℃ | Room temperature~200℃ |

| Warm-upTime(min) | Approx.12min(seting:150℃) | Approx.12mn(setng:150℃) | Approx.12min(setting:150℃) |

| Blower Motor | 150W 3PH 220VAC | 150W 3PH 220VAC | 250W 3PH 220VAC |

| PCB Width(mm) | 50~350 | 50~450 | 50-610 |

| Convoyor Direction | L-R(Option:R-L) | L-R(Option:R-L) | L-R(Opton:R-L) |

| Conveyor Speed(mm/min) | 500-1800 | 500-1800 | 500-1800 |

| Conveyor Height(mm) | 750±20 | 750±20 | 750±20 |

| Available Component Heigh (mm) | Top120,Bottom15 | Top120,Bottom15 | Top120,Bottom15 |

| Conveyor Speed Control Mode | Closed loop stepless speed regulationg Inverter | Closed loop stepless speed regulationg Inverter | Closed loop stepless speed regulationg Inverter |

| Fingers | Spring Pressing Finger/D-40Type Fingor/Double-hook Finger/Heavy type double hook f inger,Options | Heavy type double hook f inger/ Opt on:Special jig for fixture | |

| Conveyor Angle | 4-7” | 4-7° | 4-7° |

| Type of solder Pot | Motor drive | Motor drive | Motor drive |

| Solder Pot Material | Casting Iron | Casting Iron | Casting Iron |

| Wave Height Adjustment | In verte Approx:Digital Control by PC | ||

| Cooling Method | Air Cooling Option:Water cooing | ||

| Heater Power | 13.5KW | 13.5KW | 18KW |

| Solder Pot Temperature | 300℃ | 300℃ | 300℃ |

| Solder Pot Capacity | Approx 480kg | Approx.550kg | Approx.640kg |

| Wave Drive Power | 180W*2 3PH 220VAC | 180W*2 3PH 220VAC | 180W*2 3PH 220VAC |

| Solder Pot Warm-up Time | Approx.150min(seting:250℃) | Approx.150min(setting:250℃) | Approx.150min(setting:250℃) |

| Temperature Control Mode | PID | PID | PID |

| Finger Cleaning System | Brush | Brush | Brush |