Durable and interchangeable with double-sided rails with special hardening;

Adopt stainless steel belt chain with guard, anti-clamp, practical and reliable;

New flux recovery system, full modular design,convenient and quick maintenance, reduce maintenance time and cost;

Patented hot air system, more efficient, faster heat compensation;

New furnace structure design, multi-layer heat insulation,effectively reduce the working environment temperature.

SST SERIES PRODUCT FEATURES:

Durable and interchangeable with double-sided rails with special hardening;

Adopt stainless steel belt chain with guard, anti-clamp, practical and reliable;

New flux recovery system, full modular design,convenient and quick maintenance, reduce maintenance time and cost;

Patented hot air system, more efficient, faster heat compensation;

New furnace structure design, multi-layer heat insulation,effectively reduce the working environment temperature.

| SST series rel low oven main speci lica lions | ||||||

| Model No | SST-08A/SST-08N | SST-10A/SST-10N | SST-12A/SST-12N | SST-08DA/SST-08DN | SST-10DA/SST-10DN | SST-12DA/SST-12DN |

| Heating System | ||||||

| Heating Zone | 8 Heating Zones,16 Heating moudules | 10 Heating Zones,20 Heating moudules | 12 Heating Zones,24 Heating moudules | 8 Heating Zones,16 Heating moudules | 10 Heating Zones,20 Heating moudules | 12 Heating Zones,24 Heating moudules |

| Heating Length | 3120mm | 3870mm | 4635mm | 3120mm | 3870mm | 4635mm |

| Cooling Type | Three coaling zones:forced air cooling/water coaling | |||||

| Outlet Exhaust Demand,Valume | 2-Φ145, Exhaust demand15m³/minx 2 | |||||

| Conveyor System | ||||||

| Product Width | min50mm-max400mm | min50mm-max270mm(双轨同时)min50mm-max500mm(双轨单用) | ||||

| Conveying Direction | L→R,R→L | |||||

| inlet Height | 900±20mm | |||||

| Fixed Rail Side | Front rail Fixed(Option:Rear Rail Fixed) | Front and Rear Rails Fixed,central two rails are movavle | ||||

| Conveyor Type | Chain+mesh belt synchronous transmission | |||||

| Cmponent Height | Clearance based on the rail:above 30mm, below 25mm | |||||

| Conveying Speed | 300mm-2000mm/min | |||||

| Control System | ||||||

| Power Supply | AC3Φ,5W,380V,50/60HZ | |||||

| Total Power | 59KW | 73KW | 91KW | 70KW | 89KW | 108KW |

| Start up Power | 30KW | 35KW | 40KW | 35KW | 40KW | 45KW |

| Running Power | 7.5KW | 9.5KW | 11.5KW | 10KW | 11.5KW | 13KW |

| Temperature Range | Room temp to 320℃ | |||||

| Control Type | PC+PLC Control System | |||||

| Rail Width Adjusting Mode | Electric+Manual | |||||

| Temp Control accuracy | ±1℃ | |||||

| PCB Temp Deviation | ±1℃ | ±2℃ | ||||

| Data Storage | Process Data and status stotage | |||||

| Power Outage Protection | Equipped with UPS | |||||

| Operation Interface | Windows Chinese simplified, English online free switching | |||||

| General | ||||||

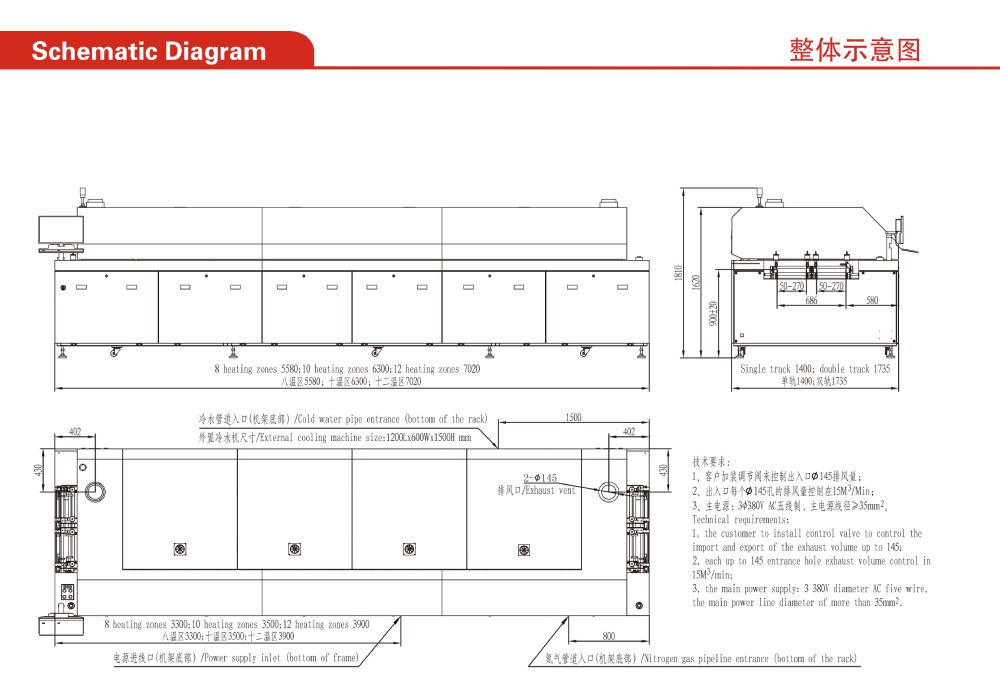

| Dimension(L×W×H) | 5580*1450*1620 | 6300*1450*1620 | 7020*1450*1620 | 5580*1735*1620 | 6300*11735*1620 | 7020*1735*1620 |

| Weight | 2200-2400kg | 2600-2800kg | 3000-3200kg | 2700-2900kg | 3000-3200kg | 3300-3500kg |

| Color | Bright wrinkled white | |||||