2024-05-14

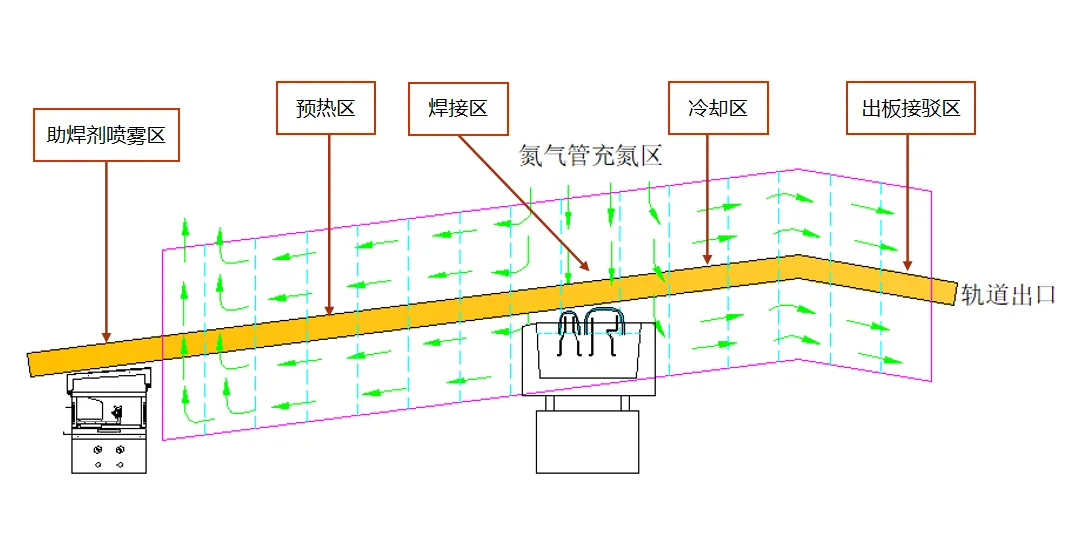

During the welding process, high temperatures are generated in the soldering area, where the solder melts and begins to flow. Oxygen in the air reacts with the solder, causing an oxide layer to form on the surface of the solder and the solder joint, which has a negative impact on the welding quality.

In the welding process, using nitrogen as a protective gas can form a gas protection layer around the component. Nitrogen is an inert gas, can effectively isolates oxygen and moisture in the air, preventing oxidation of the solder and solder joints during the welding process. This reduces defects in the solder joints. In addition, nitrogen has excellent thermal conductivity, allowing the solder to flow better, improving the wetting of the solder joints, reducing the formation of air bubbles, and resulting in smoother and more refined solder joints.

Using nitrogen in the soldering process is important for improving welding quality and increasing product reliability, especially for high-density, high-reliability, and micro-component welding. In response to this demand, SUNEAST has developed【Sealed Nitrogen Tunnel Wave Soldering Machine】

SUNEAST’s PERFECTFLOW series tunnel sealed nitrogen wave soldering machine, uses the world's first sealing solution for the soldering area and an innovative segmented conveyor system to perfectly meet the needs of flexible welding process angles and increased board bottom space, solving the problems of unsmooth board entry, width adjustment jamming and inconvenient operation and maintenance of conventional tunnel wave soldering machines. It reduce the negative effects of large wave-peak-to-solder-surface differences and maximizes the application effect of wave soldering nitrogen protection process, greatly improving the performance and welding process quality of tunnel wave soldering equipment.

PERFECTFLOW Series Features:

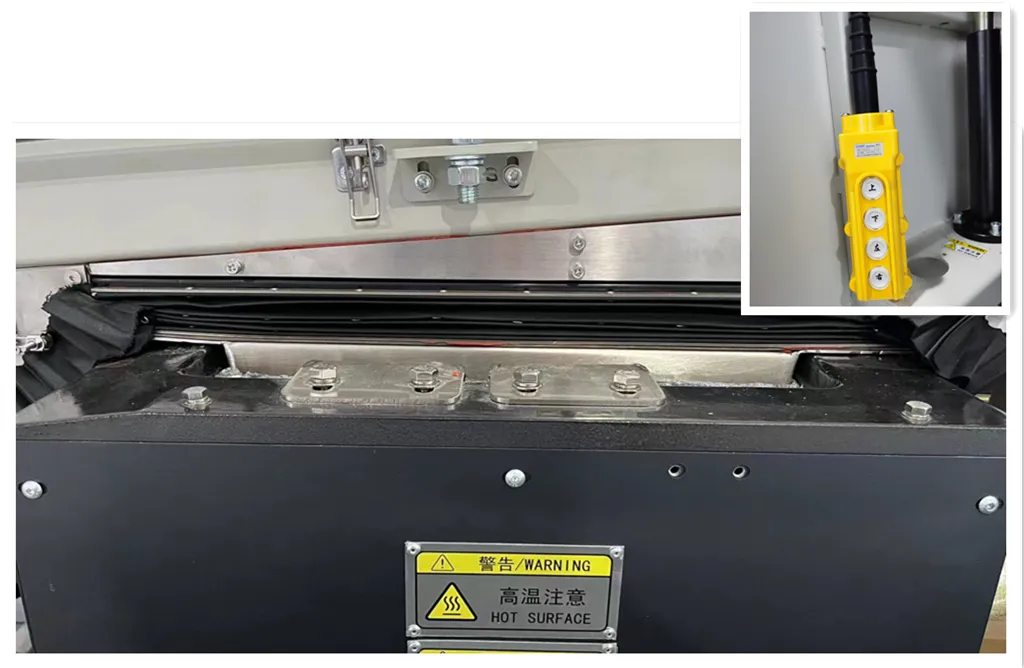

Global first sealing design for the soldering area, using special elastic materials for sealing;

Oxygen analyzer configuration, real-time monitoring of oxygen content, nitrogen protection to improve welding quality;

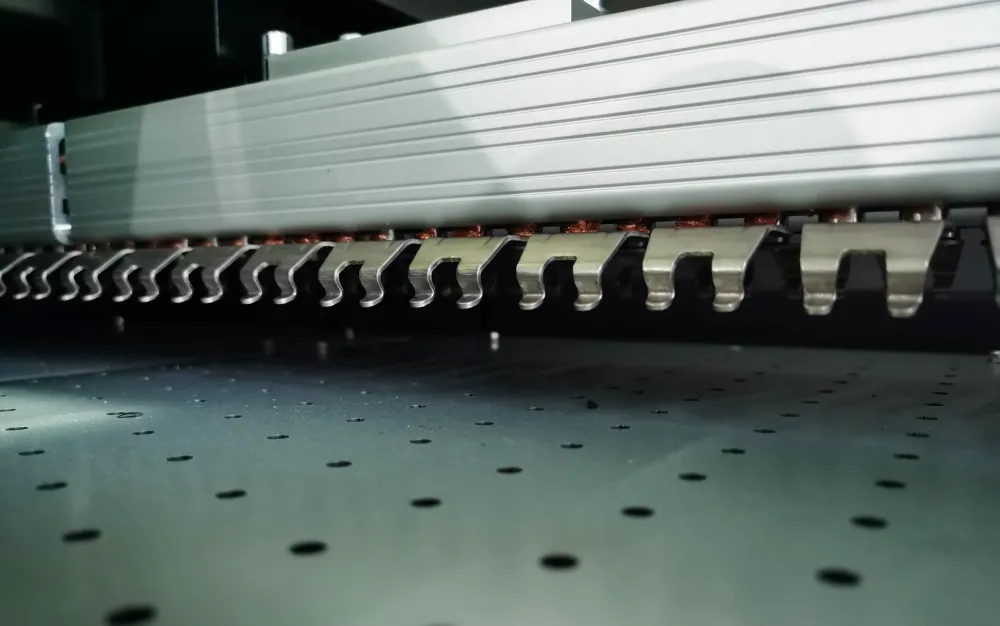

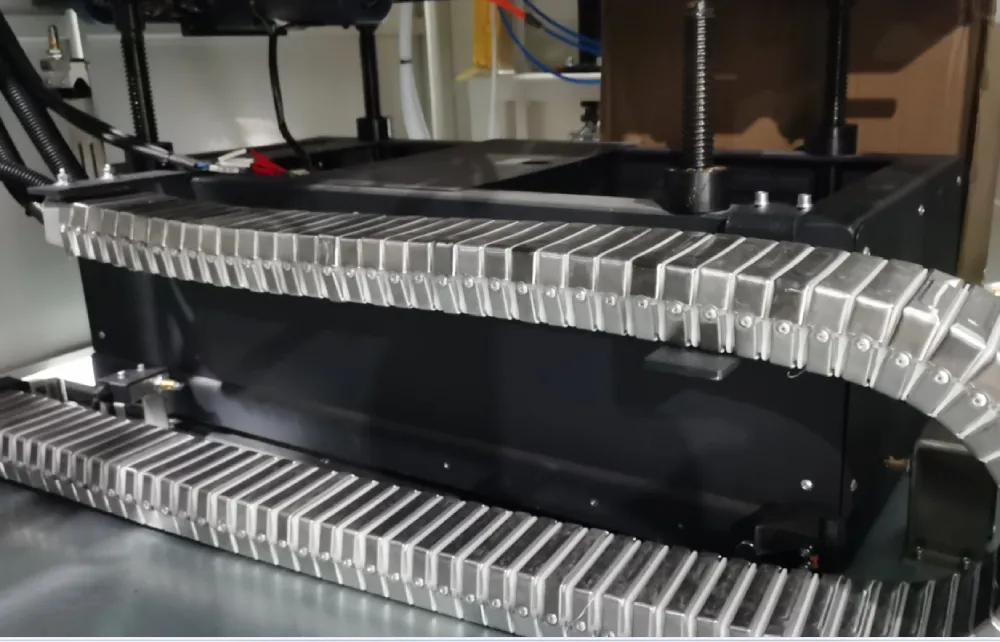

Innovative segmented conveyor design to avoid unsmooth board entry and width adjustment width adjustment jamming

Flexible adjustment of welding process angles, board bottom space can be configured as needed;

Pre-heating and solder pot transition section equipped with infrared thermal compensation to reduce the temperature drop

Sealing Structure:

The conveying section is designed with a fully sealed structure, using the world's first welding area sealing solution and an innovative design for segmented transmission. It can accurately control the airflow path to meet various nitrogen protection process requirements.

Oxygen content monitoring:

An oxygen analyzer is installed to analyze and monitor residual oxygen content.

Adjustable soldering angle:

The soldering angle is flexible and adjustable, with an adjustment range of 4.5~6.3°.

Bottom space configuration:

The bottom space of the board can be flexibly configured according to needs (25mm, larger space can be customized.)

connection:

The outlet chain connection section and wide belt conveyor section serve as an extension of the welding area on the outlet side, ensuring stable oxygen concentration levels in the welding area while also serving as a docking point with backend equipment.

Solder pot module:

The surroundings of the solder pot are sealed with special elastic materials. The electric pot can be freely lifted and free in and out;

Closed wiring:

Closed drag chains are used for wiring, ensuring safety and reliability.

Transition section thermal compensation:

The preheating and solder pot transition section is equipped with infrared thermal compensation to reduce the temperature drop.

For more detailed information and personalized customization plans, please feel free to contact us.

Email:market@suneast.com.cn