2024-09-14

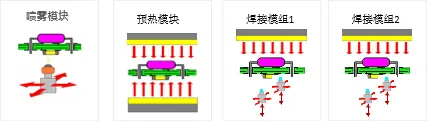

Suneast async dual pots selective soldering machine newly upgrade on the market, Z-axis independent control, suitable for different sizes of nozzles, with better compatibility. Both asynchronous control and synchronous control, greater flexibility! The dual pots +two modules solution is also available, with high capacity, greater efficiency and flexibility!

Standard: spray + preheat + solder (dual pots)

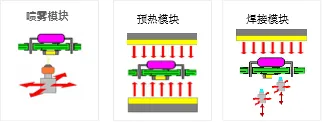

Spray module

Uses micro-hole droplet nozzle, 130um diameter, spray range 2~8mm. Servo motor motion control, point-to-point spraying, saves a lot of flux, spray accuracy ±0.25mm. Standard nozzle anti-blocking detection and automatic cleaning

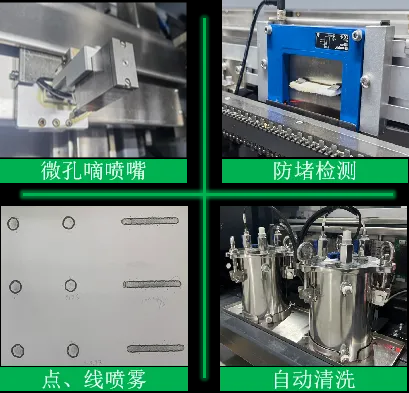

Preheating module

The preheating module consists of bottom preheating, top preheating, and heat preservation modules. Each temperature zone has independent circulation and independent temperature control. According to the product size, the heating can be automatically arranged the heating range, which is energy-saving and simple.

Soldering module

Uses micro electromagnetic pump solder pot, large flow, stable wave, and deep penetration of solder joints. The soldering platform has high motion repeatability and soldering accuracy of ±0.15mm. Nitrogen protection in the soldering area effectively reduces oxidation and prevents nozzle clogging. It can automatically calibrate the wave height, detect the liquid level height, ensure the stability of the wave, and has the function of solder joint slimming. Two CCD cameras are standard to monitor the soldering status and PCB positioning programming.

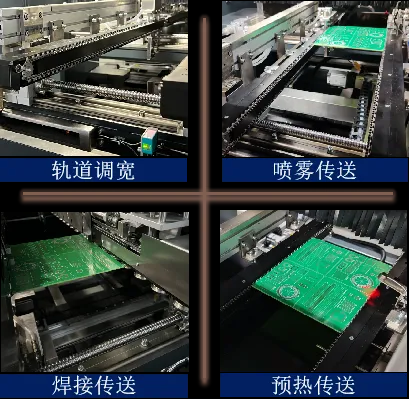

Conveyor module

The conveyor module consists of three parts: spray conveyor, preheat conveyor and soldering conveyor. It is suitable for conveying the product with process edges of more than 3mm. The spray and soldering conveyor rails are equipped with board stop devices to ensure the accuracy of spraying and soldering. The soldering conveyor adopts a roller design to effectively prevent high temperature deformation.

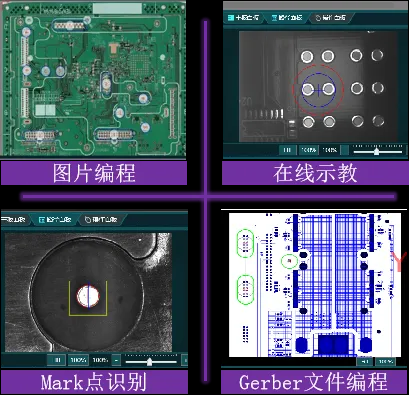

Software introduction

Supports programming in multiple ways, including CAD, Gerber, coordinate documents, and picture documents. It is equipped with a teaching camera as standard, and can be programmed online visually. It supports offline programming. Each soldering point parameter can be set independently. The whole process is visually operated, and online debugging is convenient and fast. It optimizes the soldering sequence automatically and saves soldering time. Equipped with MES system interface.

High-capacity dual-pots dual-modules solution

Standard:spray+preheat+solder1+solder2(4 solder pots)