2022-09-08

Solder paste printer is the first process of SMT production, which is also an extremely important process, solder paste printing technology is an important guarantee of solder joint quality and product quality. If not, then the rest of the production will be affected. Solder paste printer is for printing solder paste to PCB, which has the greatest impact on printing process and quality.

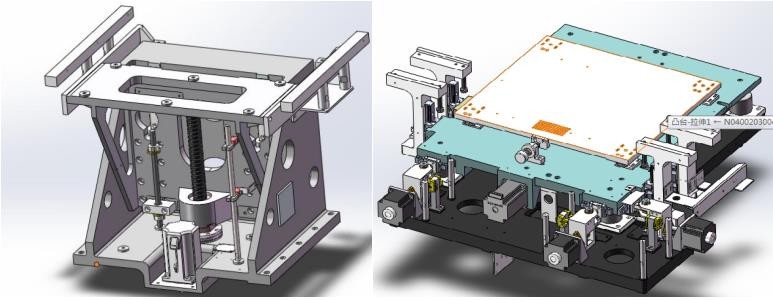

Since the first solder paste printer was independently developed in 2003 by Suneast Technology, it has been moving forward to be more precise, intelligent and stable. The main parts and components of the working platform of Suneast screen printer is optimized and designed by FEM, Finite Element Analysis method. The whole machine adopts casting process and goes through strict aging treatment and de-stressing treatment process to ensure the stability and accuracy requirements of the machine in the process of high-speed operation. Z-axis lifting adopts imported high-precision servo motor + precision lead rod + precision linear slide rail drive, high precision, strong stability. The alignment module is driven by linear motor, and the power directly acts on the platform to achieve ultra-fine precision adjustment.

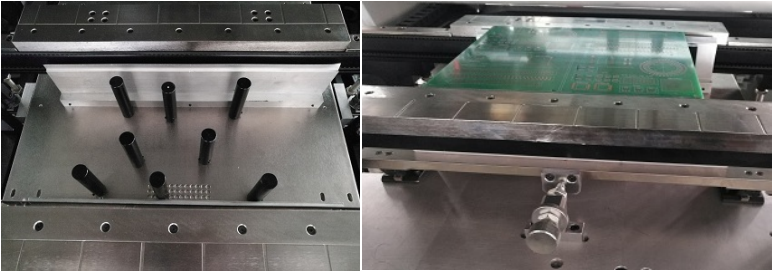

PCB support system has a variety of support functions, with magnetic thimble and edge support block, optional vacuum suction plate, make PCB support more stable. PCB clamping system can realize side clamping, up pressing and mixed clamping modes, meet the requirements of different thickness PCB clamping, and clamping fast and convenient. And the different clamping modes can be switched only by software settings.

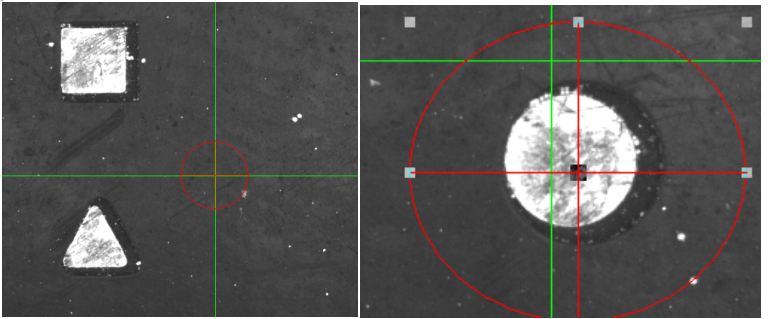

CCD visual alignment system adopts advanced MARK point recognition technology, which can identify MARK points of different shapes, to ensure high speed and high precision for the alignment of stencil and PCB. Self-developed image processing software, standard 2D detection function, and adaptive template matching function, for same pad you can directly select the frame, easy operation. Display detection process, with NG automatic alarm reminder.

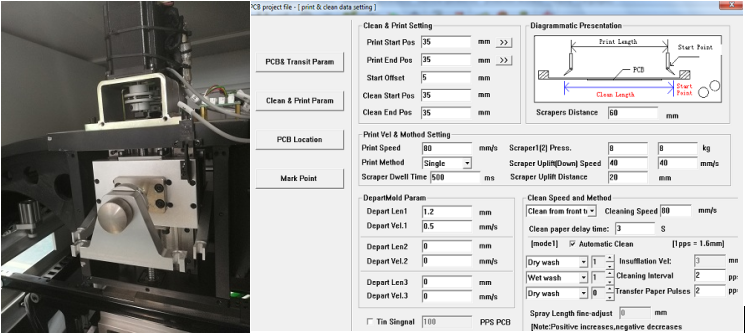

The scraper is designed with suspension scraper head to automatically balance the pressure of the scraper. The lifting motor and lead rod adopt direct connection structure to drive, longer life and more stable transmission. Multi-step grading demoulding system ensures high speed and high precision alignment. Micro-step movement mode, ensure printing quality, PC control, printing quality is even and stable.

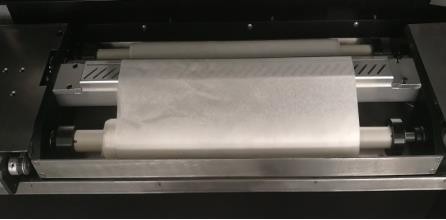

The cleaning module has dry, wet and vacuum cleaning functions, which can efficiently clean the residual solder paste in the mesh of the stencil to ensure the subsequent printing quality. Adjustable cleaning paper fixed structure, suitable for different products by using different length of cleaning paper. Paper tube symmetrical distribution before and after, and the replacement of wipe paper is simple and convenient, with automatic liquid level alarm monitoring.

The equipment has the function of one-button calibration, the machine parameters can be obtained at the same time, and the operation is quick without the need of professional personnel to actual measurement on site. Use special machine calibration template to correct the machine error regularly, automatically compensate the error value, to ensure the recovery of factory precision.

At present, Suneast Technology has five models of solder paste printer, which are suitable for different products and industries. Take a detailed understanding as below:

Automatic screen printer T3 PLUS

Features

• Auto balance squeegee pressure,pressure can be adjusted

• Intelligent 2D detection

• Dry and wet cleaning.Option: vacuum cleaning

• Option: for thin board printing

• Advanced mark point recognition technology and stable system capability

• The first online calibration technology in China

Automatic screen printer T5

Features

• Integral welded frame

• Multifunctional platform design

• Visual alignment to ensure the accuracy

• Integral conveying system

• Independent cleaning structure

• Squeegee lifting is directly connected with the screw rod structure

Full automatic visual screen printer T9

Features

• Intelligent, high precision PCB thickness adjustment platform jacking mechanism

• Adopt German imported screw, more stable operation, more accurate positioning

• The first online calibration technology in China

• Intelligent 2D check

Full automatic visual screen printer SL120

Features

• Perfect solution for large size product printing

• Easy calibration and maintenance

• Stable printing quality

• Independent developed image processing software

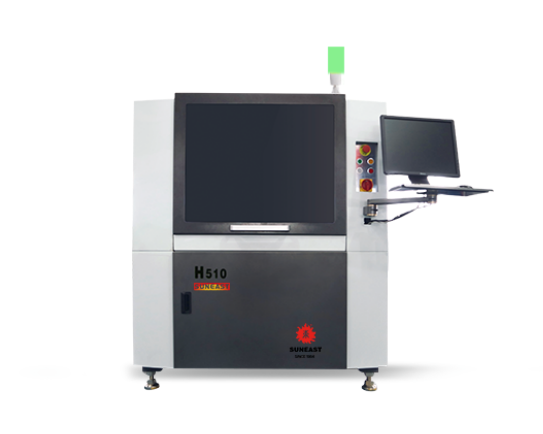

Automatic screen printer H510

Features

• Applicate linear motor - high speed and high precision

• The printing leader of 03015 micro component

•New mechanical design-more stable and convenient

• New printing head design-high printing quality

In the future, in order to meet the decreasing component size and the development of high-density electronic packaging technology such as QFP, BGA, SOP, CSP, etc., the screen printer will need to continuously improve the printing accuracy and reduce the correction error to meet the strict production requirements. Suneast Technology will always be market demand-oriented, customer-centered and constantly drive innovation, relying on strong strength, leading technology, to provide precision, stable, intelligent solder paste printing equipment solutions.