2022-08-11

As the key carrier of automobile electronic control system, the quality of automobile board is related to the safety and reliability of the whole car. Automobile board is different from the general PCB, normally it uses thick copper, metal-base, and ceramic base (for heat dissipation and large current, and the buried copper block), the temperature and current bearing automobile board are higher than the general PCB.

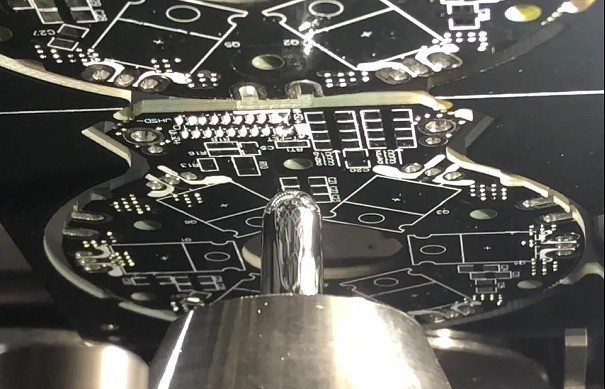

The automobile board usually uses high-density double-sided PCB, and contains a certain number of through-hole components, which features in small space, high solder joint quality requirements, and no-clean. With the increasing difficulty of automotive PCB components welding, manual welding and dip welding cannot meet the requirements of automotive board welding, and the application of selective wave soldering equipment in the automotive electronics industry more and more. For large heat capacity and multi-layer circuit boards, dip welding is difficult to meet the tin penetration requirements, and the selective soldering is different, the dynamic tin wave from the welding nozzle will improve the vertical tin penetration in the through hole, especially for lead-free welding, because the lead-free process is poor wetting, and it needs the powerful dynamic tin wave.

After the actual verification, Suneast technology selective wave soldering in the automotive electronics industry has achieved a very good application effect. It can save about 95% flux by controlling flux spraying range and volume during flux spraying, and ensure good spraying effect. The preheating module adopts sectional control, with automatic temperature correction function, which can not only meet the high temperature required by the automobile board, but also save the power consumption of the equipment. The use of nitrogen can increase the solderability of lead-free solder by 4times. The solder pot with electromagnetic pump provides a stable peak height, and the parameters can be set separately for each solder spot to ensure high quality soldering.

Suneast technology selective soldering has the following characteristics for automobile board welding:

Adopts the solder pot with micro electromagnetic pump, high tin wave, large flow, stable peak wave, deep solder penetration, powerful wetting and welding.

Adopts nitrogen filling protection around the nozzle around and surface of the soldering, which can improve the solderability of lead-free soldering, and reduce the tin dross production to prevent nozzle jam, save welding costs and labor costs;

The soldering nozzle has high temperature resistance, corrosion resistance, strong oxidation resistance, and good infiltration. The normal use time can be up to 3 months.

Automatic solder liquid height detection, to ensure the stability of the wave peak.

Solder joint slimming function.

Equipped with two CCD cameras, which is used to monitor welding status and PCB positioning programming.

Spraying and welding transmission track are respectively equipped with stop board positioning unit to ensure spraying and welding accuracy;

The welding transmission roller design can effectively prevent high temperature deformation, to ensure the weldable distance of PCB edge is much higher than the chain transmission structure.

Infrared + hot air combined preheating module, drawer type structure. Fast preheating, uniform temperature, fully reduce the temperature difference between large and small components, and the equipment maintenance is convenient.

After completing the selective wave welding, the surface of the solder joint is smooth and full, and the "non-contact" welding avoids the damage of the circuit board components of the automobile, which provides a high-precision and high-reliability welding solution for the automotive electronics industry. In addition, according to the requirements of different products, there are a variety of models to choose, according to the needs of improving production capacity, Suneast can provide high capacity equipment combination scheme.