2022-08-11

The characteristics and process requirements of Mini LED packaging and curing:

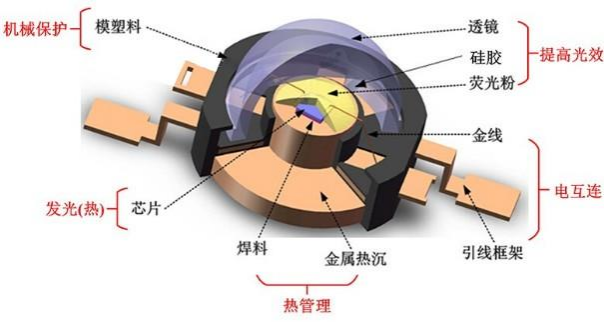

LED (semiconductor LED) packaging refers to the packaging of light-emitting chips, compared to integrated circuit packaging, it is very different. LED package is not only required to protect the wick, but also to be lighttight. Mini LED is sub-millimeter light emitting diode, refers to the chip size between 50 and 200μm. Mini LED is developed to solve the problem that the particle size of the traditional LED partition control is not fine enough. It has the advantages of "thin film, small and array" in the application, and has a broad market prospect. Its crystals are smaller, more crystals can be embedded in a backlit panel per unit area, and more backlit beads can be integrated on the same screen.

Mini LED chip package is glued; the chip and bracket are wrapped with glue, with long curing to let the glue solidify. The quality of the glue curing process directly determines the final quality of Mini LED, such as brightness and electrical parameters. Therefore, the packaging of Mini LED not only has special requirements for packaging materials, but also has higher requirements for packaging and curing process and equipment.

The traditional off-line curing oven requires manual handling for products, low production efficiency, high energy consumption and high cost. Many customers require connecting other equipment to form the entire automated production shop, reduce the operators, at the same time, and require improving capacity and efficiency. Especially for Mini LED products with small size, large number and high curing requirements, Suneast Technology has developed online multi-channel tunnel oven to meet the growing market demand.

Suneast Technology multi-channel tunnel oven adopts modular design concept, easy to operate, convenient maintenance, reduce handling, and save labor costs for customers; the overall energy consumption is low, compared with the traditional oven, the energy consumption is reduced by 50%, saving the use cost for customers; adopt multi-channel guide rail chain transmission, greatly improve the capacity; it can be connected with automatic production line to effectively control manpower and improve product quality.

Suneast technology tunnel oven is composed of the rack, chamber, hot air circulation system, guide chain transmission unit, heating system and electric control system, such as adopting modular, digital and section design, its function, performance, stability, security, reliability, maintainability, operability and humanization has the advantages of good.

Suneast Technology multi-channel tunnel oven has the following characteristics for Mini LED chip packaging and curing:

The whole machine adopts segmented module unit design, convenient disassembly and assembly, strong expansion. Furnace open design, using electric cylinder support, the oven can be opened on one side;

The conveying system adopts multi-channel guide rail chain transmission, which can convey multiple fixtures at the same time, with high production efficiency;

Double-sided guide rail treated with super hardening, high loading, wear resistance, and not easy to deformation. With in/out buffering structure, using roller drive, with automatic lubrication device;

Use high-power motor, high thermal efficiency, hot air circulation in the heating box, patent air channel structure design (patent No. : 201721160420.1), front and rear return air circulation, better temperature uniformity. Compared with the traditional oven, the equipment can save power more than 50%;

The heating adopts high efficiency heating pipe, long service life, drawer type insertion, easy to replace;

Adopts sectional temperature control, to adapt to product process changes, high temperature control accuracy, and stable quality;

Powerful and stable control system to ensure the stable operation;

It can be used with automatic production line, effective control of manpower, reduce handling time, save costs.

At present, Suneast Technology multi-channel tunnel oven has been mature and applied to Mini LED chip packaging and curing, semiconductor, automotive electronics, electronics, motor, communication and other manufacturing enterprises, all indicators have reached the industry excellent level. Suneast can customize the personalized equipment according to the enterprise products, and the professional engineers will evaluate, guide and train the installation in the whole process to ensure the normal operation and use of the equipment. Welcome inquiry.