2022-06-30

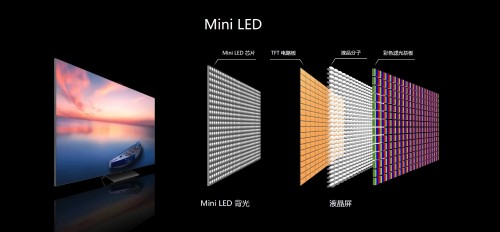

Mini LED refers to the size of LED chips between 50-200μm, is the result of small spacing LED further refinement. Compared with traditional LED, Mini LED has higher resolution and superior display effect, smaller particle size, for making thinner screen, faster response speed, and higher high temperature reliability. At the same time, it can save more energy than traditional LED, and the light changes function is more precisely, without the problem of uneven LED backlight. With the rapid development of Mini LED display technology, Mini LED has been applied to large-screen and HIGH-DEFINITION display fields, such as monitoring command, HIGH-DEFINITION broadcasting, advertising display, medical diagnosis, smart phones, automotive panels and other products.

However, there are still many challenges in the practical application of Mini LED. The solder pad of Mini-LED is very small (about 100um), the solder paste quantity is also less, and the chip is smaller. At the same time, Mini LED mostly adopts integrated packaging (COB), which has high requirements for stability and consistency in the process of operation. Therefore, the realization of stable and reliable chip and substrate welding in the packaging process is one of the most important steps in the application process of Mini LED. Each Mini LED circuit board typically has thousands of chips and tens of thousands of solder joints to connect RGB tri-color chips. Such a large number of solder joints bring great difficulty to chip packaging welding. Due to the small particle size of Mini LED pads, there are higher requirements for reflow welding of hot air/cooling air volume control, temperature uniformity, nitrogen protection, oxygen content in the furnace and so on.

Mini LED reflow welding equipment solution:

In the face of these problems, Suneast technology continues to study Mini LED process, using years of welding technology experience and industry application experience, to explore the full nitrogen filling reflow oven that can meet the requirements of Mini LED welding.

Full nitrogen filled reflow oven has the following characteristics for Mini LED industry welding:

1. The equipment adopts segmented independent temperature control, each section is controlled by the separate inverter, which can effectively control the volume of hot air in each temperature zone, to ensure the temperature uniformity, the transverse temperature difference is controlled within 1℃;

2. The whole process is filled with nitrogen, and the nitrogen in each temperature zone is adjusted independently to ensure uniform and reliable nitrogen in the furnace;

3. With upper and lower double cooling zones, independent inverter control, effectively control the cooling slope;

4. Equipped with high-precision oxygen analyzer, multi-point oxygen concentration detection in the furnace, real-time detection of oxygen content data in each process section of the furnace, and the oxygen content can reach below 50PPM;

5. Use multistage filtration for flux recovery, with an independent recycling box, the recycling is more thoroughly, to keep the furnace clean, save maintenance time, and reduce the cost of use;

6. It can meet the requirements of thousands, ten thousand times cleanliness production environment.

At present, Mini LED display industry has entered a new stage of integration of application and technology innovation. Suneast Technology will continue to develop key technologies, strengthen the technical upgrade of Mini LED welding equipment, provide customers with high-quality equipment and professional supporting services, and promote the improvement of Mini LED technology.