2022-06-30

With the rapid development of electronic technology, the trend of electronic components miniaturization, chip, complex and multi-function will be further strengthened. The increasing servicing capability and precision of electronic components, as well as the increasing degree of production automation, are increasing the demand for bottom-filling and packaging curing technologies. The traditional curing oven has problems, such as occupying a large area, using more labor, high energy consumption and unstable quality. The on-line vertical oven equipment of Suneast Technology provides high efficiency, high quality and high cleanliness package curing solution for the current demand, which is widely used in the production of chip bonding, bottom filling, component packaging and other hot curing processes.

Suneast online vertical oven, with compact structure, small footprint, it saves workshop space greatly; high production efficiency, much higher than the traditional curing oven, especially for products requiring long baking time in the oven, it can effectively improve production capacity.

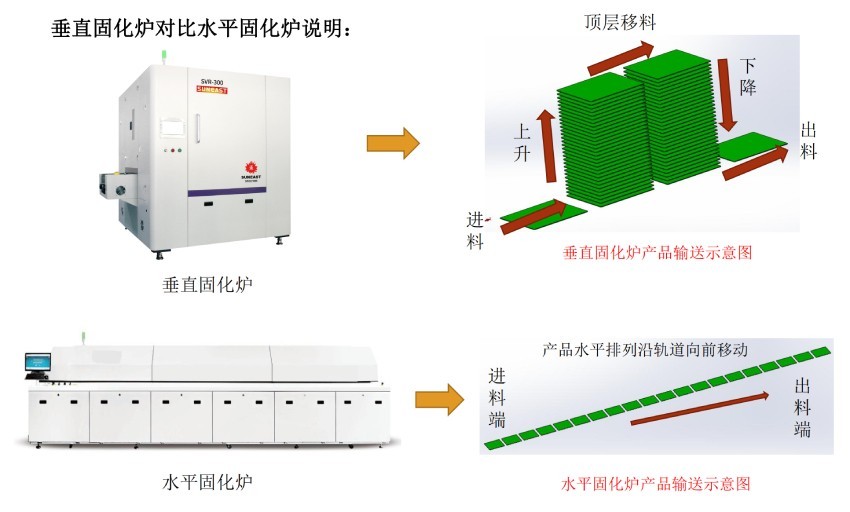

Comparison of the traditional and vertical ovens:

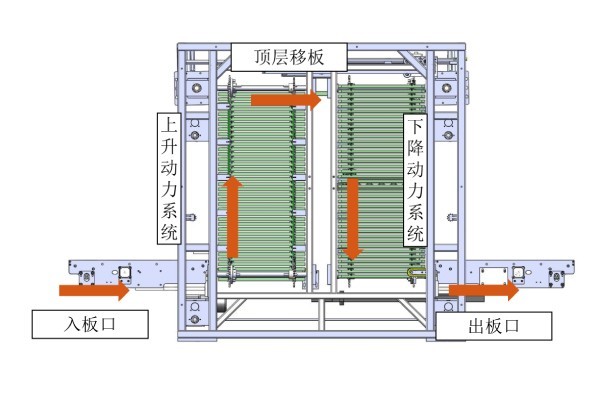

Suneast online vertical oven adopts double lifting design, large number of storage boards and accurate temperature control can meet the requirements of various temperature profiles curing process. The inlet and outlet side are equipped with standard SMEMA communication interface, connected to the previous and next computers, automatic control of the board. The push board mechanism adopts high precision stepping motor control, to ensure the accuracy of board pushing. Imported optical fiber sensor is used to detect PCB conveying in the furnace chamber to ensure maximum reliability of operation.

Suneast vertical oven heating system uses 12 heating modules in front and rear side (number of heating modules: 12 modules, 8 modules or special requirements. It is determined according to the effective heating height of the machine, the amount of heat absorption of customer products and the sensitivity to temperature uniformity. In the case of meeting the product process, the fewer heating modules, the higher the cost performance), and the higher the thermal compensation efficiency will be. Each module independently controls the temperature and monitors the temperature change in real time to ensure that the temperature deviation in the furnace is ≤±2℃.

The top of the machine is provided with a fast air outlet for cooling, which can quickly cool the temperature in the furnace if the equipment is abnormal, so as to inspect the machine easily; the exhaust air outlet is configured to keep the air in the furnace chamber clean. Glass Windows are installed on the inlet side and outlet side of the equipment to facilitate real-time observation of the operating conditions in the furnace.

Advantages of vertical oven:

1. Small footprint and space saving:

Compared with horizontal curing oven, the length of horizontal curing oven (product horizontal storage) is 10 times or more than that of vertical oven (product vertical storage) at the same capacity.

2. Improve the curing quality:

Refer to the measured temperature curve of the vertical oven that compared with the traditional oven, the online automatic production of the vertical oven has better temperature uniformity and curing consistency, which effectively ensures the product quality.

3. Reduce the cost of use:

The running power of vertical oven is lower than the horizontal oven, which will save your cost over time. In addition, on-line vertical oven does not need people to load and unload the materials, which can save labor.

4. Increase production capacity:

Under the same processing time, vertical oven can store more products, with faster production time. Compared with the traditional off-line oven, it can save the time for the staff to load and unload materials, continuous production, and effectively improve the capacity.

5. It can meet the requirements of high cleanliness: Suneast vertical oven can meet the requirements of thousand times, ten thousand times cleanliness production environment.

At present, there is a growing demand for vertical oven in the market. It has become a trend to replace the traditional curing oven. Welcome to inquire and consult it.