2022-06-10

With the development of electronic technology, SMT components become smaller and diversified, and the number of through-hole components is gradually reduced, and it is increasingly difficult to weld through-hole components (such as components with large heat capacity or small spacing), especially for products requiring high reliability. The welding methods of through-hole components mainly include manual welding, wave soldering and selective wave soldering. The quality of manual welding depends on the operator's working skills and proficiency, poor repeatability, low controllability, not suitable for large-batch automated production, and labor costs increase year by year, it has been gradually eliminated by enterprises. The ordinary wave soldering needs to customize the fixtures, all solder joints in the same set parameters to complete the welding, which cannot realize the welding quality of all components (for example, some parts are always bad tin penetration or bridge defects), so that wave welding had to repair welding, reduce the long-term reliability of the product. In addition, the secondary melting of solder joints of adjacent components may occur during the heating process of wave soldering.

In order to solve this actual demand, equipment enterprises research and develop the selective wave soldering machine, Suneast technology is one of the earliest domestic enterprise to research and develop and produce selective welding equipment. Selective wave soldering can be set each solder joint parameters separately, including each welding flux spraying volume, welding time, wave height, drag welding speed which can be set and adjusted. The engineers have enough process adjustment space to adjust the parameters of each solder joint to be best, so the welding quality is high and the consistency is good. The most obvious difference between selective welding and the tranditional wave soldering is that in wave soldering, the lower part of the PCB is completely immersed in the liquid solder, whereas in selective welding, only a certain area is in contact with the solder wave.

Selective wave soldering is mainly composed of flux spray module, preheating module, welding module, conveyor system, and mechanical positioning module. According to the needs of different application, Suneast Technology chooses the following types of welding equipment:

1、Single pump selective soldering SUNFLOW 3 composition: spray module + preheating module + single pump welding module

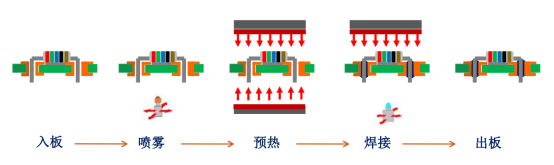

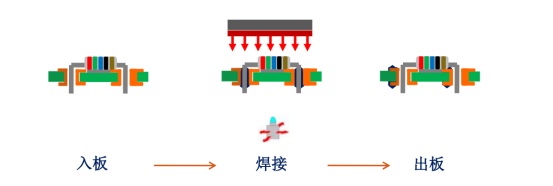

(SUNFLOW 3 Work flow chart)

Features: SUNFLOW 3 is an all-in-one welding standard machine, spraying, preheating and welding module can work at the same time, continuous PCB feeding, high production efficiency, single pump work, flexible welding. Support online/offline programming, the welding parameters can be set independently for each solder joint; can do double-sided PCB welding, the whole process welding status is displayed.

2、Double pump welding SUNFLOW DS: spraying module + preheating module + double pump welding module

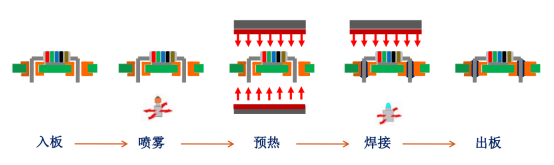

(SUNFLOW DS工作流程图Work flow chart)

Features: SUNFLOW DS uses drip nozzle which is imported from Germany, with high precision and convenient replacement of nozzle. Double electromagnetic pump design, efficiency increase 1 times, double pump work at the same time, the spacing between the two nozzles can be adjusted automatically. The wave height is stable, maintenance rate is very low, welding process can be recorded.

3、SUNFLOW FS consists of spraying module + preheating module + single pump welding module

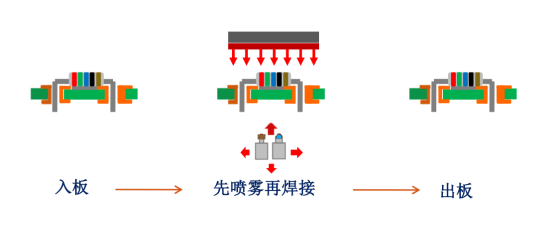

(SUNFLOW FS Work flow chart)

Features: SUNFLOW FS integrated spray/preheat/weld function. Compact design, small footprint, energy saving; quick change over.

4、Composition of independent welding machine SUNFLOW S: welding module

(SUNFLOW S Work flow chart)

Features: SUNFLOW S is an independent welding module, modular design, easy maintenance. It can be used with SUNFLOW 3 to improve production efficiency and more flexible.

5、Flexible solutions for high productivity:

→Modular design meets the requirements of flexibility and high productivity

→Suitable for panel, double the productivity;

→To meet the needs of two kinds of the nozzle to complete the production;

Suneast selective wave soldering has the following characteristics:

1. The spray nozzle is imported from Germany, which is equipped with automatic cleaning function to prevent the nozzle from jamming;

2, The welding nozzle adopts special material and technology, with long service life;

3, Adopts segmented preheating, automatic adjustment according to PCB size, energy saving;

4, Germany imported electromagnetic pump solder pot, special treatment of leading tube, non-wetting, corrosion resistance;

5, The platform adopts precision screw, full servo motor control, super stability, with high precision;

6, Standard teaching camera, support pictures, Gerber files, CAD files; online teaching programming, simple programming, high efficiency; welding path graphic visualization, convenient parameter positioning, simple debugging.

The selective soldering machine of Suneast technology is mainly suitable for welding of through-hole components in high-end electronic products, such as automotive electronics, military industry, aerospace, industrial control, communication and other products with high welding reliability requirements. In the future, the development of product technology will promote the wider application of selective welding equipment, and Suneast technology will increase efficiency and improve quality for enterprises with high-quality equipment.