Customized stainless steel board supporting chain+rail conveyor, with less running wear,long service life, more stable and reliable.

Multi-channel design, greatly expand the capacity of products in the furnace, large capacity.

It can be configured with multi-channel connection, which can realize automatic loadingand unloading and reduce labor cost.

Customized stainless steel board supporting chain+rail conveyor, with less running wear,long service life, more stable and reliable.

Multi-channel design, greatly expand the capacity of products in the furnace, large capacity.

It can be configured with multi-channel connection, which can realize automatic loadingand unloading and reduce labor cost.

Full modular design, convenient maintenance, reduce maintenance time and cost.

Patented hotair system, more efficient hotair convection conduction, faster heat compensation.

New furnace structure design, multi-layer heat insulation, effectively reduce the workingenvironment temperature.

Suitable for magazine type curing;

Suitable for multi-channel conveying(6-channel, 10-channel, 16-channel, etc.) ;

Suitable for Mini LED solidification baking required for long curing time, large production capacity and highcuring requirements;

Suitable for PCB, LED, Mini LED, capacitor, powersupply and other components baking process;

It covers a wide range of fields electronic products, automotive electronics, semiconductors, 3C products, etc.

| SHR-01B Series Specification | ||

| Model | SHR-01B(01-08T-C06) | Remarks |

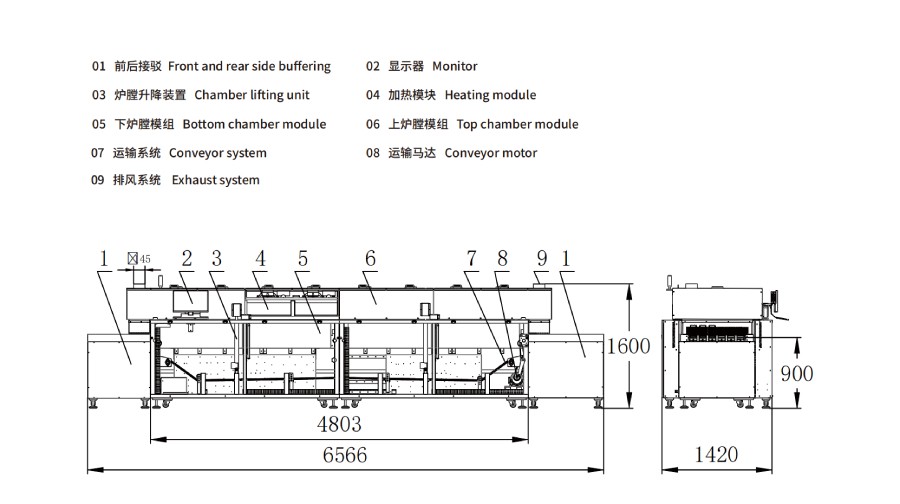

| Dimension | L6566xW1420xH1685mm | |

| Weight | Approx.1400kg | |

| Power Supply | 3P5L 380V 50/60Hz | |

| Control system | PC+PLC | |

| Total Power | Approx.45KW | |

| Conveying Type | Stainless steel customized supporting chain | |

| Channels | 6 Channels | |

| Product height (including fixture) | L162*W68-82*H160mm | |

| Infeed height | 900±20mm | |

| Conveying Speed | 30-150mm/min | |

| Speed control mode | Closed Ioop stepless speed regulation by inverter | |

| Conveying direction | L-R(Option:R-L) | |

| Temperature control mode | PID | |

| Temperature range | Room temp~200℃ | |

| Heating system | Heating on the channel | |

| Heating zones | 8 heating zones | |

| Heating zone length | 4800mm | |

| Cooling zone length | N/A | Option |

| Warming up time | Approx.15min | Set temp 150℃ |

| Running power | Approx.6KW | |

| Temperature value display accuracy | 1℃ | |

| Abnormal alarm | Three-color signal light+ human-machine interface alarm | |

| Exhaust requirement | 2-Φ150 air outlet,the exhaust air volume of a single air outlet is about 15m³/min | |

| Parameter storage | Process Data and status stotage | |

| Power cut protection | Equipped with UPS | |

| Air source | N/A | |