Case details

PLC control industry product characteristics and the selective soldering process requirements:

PLC is a digital operation electronic system designed for application in industrial environment. It uses a programmable memory, in its internal storage to perform logical operations, sequential control, timing, counting and arithmetic operations and other operation orders, through digital or analog input/output control various types of machinery or production process, its products are widely used in communications, automotive electronics, automation machinery industry and other fields. PLC internal main body is MCU (microprocessor), DSP (digital signal processor) CPLD (logic programming), capacitance, inductance, IO terminals and other components.

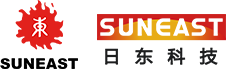

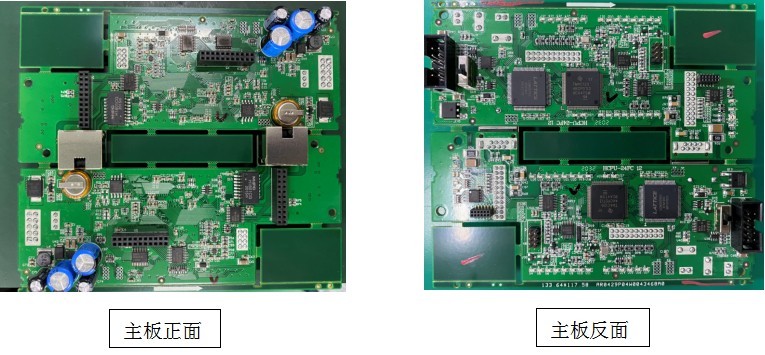

PLC control mainboard consists of plug-in and SMT components, the components size difference is big, and the product components welding has high requirements of performance, in order to ensure that the welding performance at the same time to ensure that no damage to other components.

Suneast technology selective soldering equipment solution:

For the welding of the components on the PLC control mainboard, the selective soldering machine only sprays the flux for the components that need to be welded, and ensure that the flux spraying on the welding pad is uniform, at the same time, ensure not to affect other components. The preheating module adopts segmented control, and the whole preheating range can be set according to the size of the product, which can not only meet the welding preheating temperature, but also save the power consumption. The welding nozzle is selected according to the distance between the components on the board and the welding requirement, with different sizes and models to ensure the welding quality.

Suneast selective soldering for PLC mainboard welding has the following characteristics:

1. Conveying chain combine with roller structure, smooth transport.

2. Adopts the imported drop nozzle, the flux spraying is more uniform, and the through hole penetration is stronger.

3. Independent infrared + hot air combined mixed preheating module, fast preheating, uniform temperature, and convenient maintenance.

4. Equipped with different size nozzle, suitable for welding different components, to meet the welding quality.