Case details

Product characteristics and wave soldering process requirements of home appliance industry:

Household appliances (referred to as home appliances) mainly refer to all kinds of electrical appliances and electronic appliances used in homes and similar places. Also known as civilian appliances, household appliances. Household appliances have become the necessities of modern family life and are closely related to everyone's life.

The classification of household appliances has not been unified in the world. However, it is common to classify according to their functions and application, which can be roughly divided into 8 categories:

① Refrigeration appliances;

② Sir conditioner;

③ Clean electrical appliances;

④ Kitchen appliances;

⑤ Electric heating appliances;

⑥ Beauty and health appliances;

⑦ Audio and video appliances;

⑧ Other electrical appliances, such as fireworks alarm, electric bell, etc.

Suneast wave soldering application solution in appliance products:

The control board of home appliance (main board) and power supply board are similar, it not only provides power, but also plays the role of control program action to home appliance. Because home appliances are required to have a long service life, so the solder joint requirements of the control board are also extremely strict. The solder joint cannot have virtual welding, false welding, air holes and other poor welding. When there are vibration, knock against on the appliances, the solder joints of the control board (motherboard) cannot loose, and even fall off. Once such a situation occurs, after-sales service is a must, and even need completely replacement of the control board. It does not only bring economic lost to consumers, and gives shock to the consumer confidence.

Suneast wave welding characteristics in the control board (motherboard) welding of home appliance industry:

1. The conveyor system adopts heavy type finger. Most of the home appliance control board is produced with fixture and heavy. The heavy type finger structure can prevent deformation, and promise smooth transportation.

2. Vertical spraying patented technology, spray more uniform, through-hole penetration is stronger, good for solder climbing.

3. Infrared + hot air combined mixed preheating module, drawer type structure. Fast preheating, uniform temperature; fully reduce the temperature difference between large and small components, convenient for maintenance.

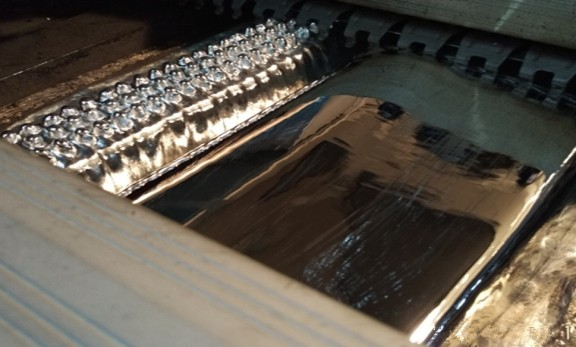

4. The unique mirror waveform nozzle structure of Suneast technology is suitable for welding all household appliances control board (main board), its wave peak stability is excellent, fully ensure the stability and consistency of welding quality.

5. For welding the SMT components and the plug-in parts on the control board, Suneast technology turbulence wave can fully ensure the welding quality of the shadow part of the SMT components, no leakage welding, no joints welding.

6. Forced natural air up and down fast cooling, good for welding quality.