Case details

The characteristics of new energy automobile industry and its product process requirements:

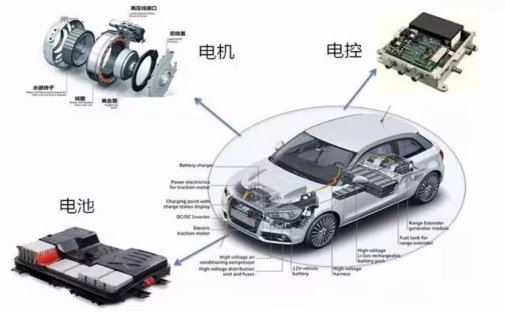

New energy automobile refers to the vehicles that adopt unconventional vehicle fuel as a power source(or use conventional vehicle fuel and adopt new vehicle power devices),it integrates the advanced technology of vehicle power control and drive,and forms the vehicles with advanced technical principles,new technology and new structure.

The core technology of new energy vehicles is the"three electric",that is,battery,electric drive and electronic control.And the most core is the electronic control module.

The electronic control system should have high control precision,high dynamic response speed,and provide high safety and reliability.This requires that the electric control board not only has reliable welding quality,but also can withstand high frequency vibration and wet environment after installation and fixed.

The electronic control module is filled with glue,wrapped with glue,and then baked to allow the glue to solidify,which can effectively cope with vibration,humidity and other harsh conditions.The quality of the glue curing process directly affects the quality of the electric control system and the final quality of the control parameters.

(Electric control module for heating and curing in tunnel oven after filling glue)

As shown in the picture above;

Specific process requirements:the weight of a single product is up to 75Kg,the length,width and height are up to 500mm,the curing temperature is 105℃,the curing time is 20mins,and the temperature uniformity is±5℃.Productivity requirement:1min/pcs.

Suneast Tunnel Oven Configuration

Suneast tunnel oven’s characteristics for the packaging and curing of the electric control system of new energy automobiles:

1,The equipment adopts online conveying,which can be used with automatic production line,effectively control manpower input.

2,Equip with heavy-duty industrial roller conveyor chain+high-power motor,effectively cope with high load conveying requirements.

3.The heating section adopts modular design,which can flexibly design the length of the heating section according to the requirements of production capacity,so as to meet the needs of various processes.

4,The heating module adopts high efficiency heating tubes,with long service life,drawer type module,easy to remove and replace.

5.Patented air flow structure design(patent No.:201721160420.1),efficient heating module,back and forth air circulation mode,better temperature uniformity,higher thermal efficiency,which can effectively ensure curing quality.

6,The heating chamber adopts the heating module modular design,which is easy to remove and open,convenient equipment maintenance and abnormal handling.

7,The equipment adopts PC+PLC control mode,friendly man-machine interface,easy to operate and use,and it can be flexibly configured for various functions,such as MES,barcode scanner and so on.

After years of technical accumulation,Suneast tunnel oven has been widely used in automotive electronics,semiconductor industry,the related component packaging process,including electronics,motor,communication and other industries.