Case details

Industry characteristics and process requirements of Mini-LED packaging curing:

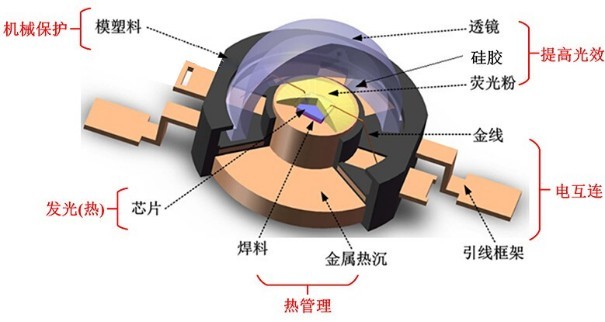

LED (semiconductor light-emitting diode) packaging refers to the packaging of light-emitting chips, which has a great difference, compared with integrated circuit packaging. The packaging of LED is not only required to protect the wick, but also to be able to transmit light. Therefore, the PACKAGING of LED not only has special requirements for packaging materials, but also has higher requirements for packaging curing equipment.

Mini LED is a sub-millimeter light-emitting diode, which the chip size is between 50 and 200μm. Mini LED is developed to solve the problem that the light granularity of traditional LED partition control is not fine enough. The luminous crystal is smaller, the number of crystals can be embedded in the backlight panel per unit area is more, and more backlight beads can be integrated on the same screen.

Mini LED chip is filled with glue, the chip and bracket are wrapped with glue, and then baking for long time and solidified by glue. The solidification process of the glue directly determines the final quality of Mini LED brightness and electrical parameters.

Suneast technology multi-channel tunnel oven solution:

Due to the small size, large quantity and high requirements of Mini LED, the packaging curing of Mini LED is especially suitable for using Suneast Technology multi-channel tunnel oven. The production efficiency of Suneast multi-channel tunnel oven is high; especially for long baking time requirement, which can effectively improve productivity and segmented temperature control to adapt to different product processes. The temperature uniformity is good and the quality is stable.

Suneast technology multi-channel tunnel oven adopts modular design concept, easy to operate, convenient and fast maintenance, reduce handling, save labor costs for customers; Low cost operation design, compared with the normal oven, energy saving 50%, to save the use of cost for customers; Multi-channel rail chain transmission, compared with the traditional oven, it belongs to the high output, to meet customer capacity demand; It can be used with automatic assembly line to effectively control manpower and improve product quality.

Suneast technology multi-channel tunnel oven has the following characteristics for Mini LED chip packaging curing:

1. Multi-channel rail chain transmission, high production efficiency, especially for the product which requires long time baking time, it can effectively improve productivity;

2. High-power motor, high thermal efficiency, heating box hot air internal circulation, the energy saving rate is more than 50% than traditional oven;

3. Segmented temperature control, in order to adapt to product process changes, good temperature uniformity, stable quality;

4. It can be used with automatic production line to effectively control manpower, reduce handling time and save input cost.

5. The inlet and outlet buffering use roller transmission;

6. High efficiency heating tube, long service life, drawer type design which is easy to replace;

7. Patented air duct structure design (patent No. : 201721160420.1), efficient heating module, front and back air circulation, better temperature uniformity, higher thermal efficiency;

8. The furnace opening design use electric cylinder support, and the whole furnace opening is on one side;

9. Modular segmented design, convenient disassembly;

10. Powerful and high stability control system