2017-11-10

The 23rd NEPCON South China

Time: 29th ~31st August, 2017

Address: 1D65, Hall No.1, Exhibition Center of Shenzhen

Booth No.: 1D65

During 29th ~31st August 2017, the 23rd NEPCON South China 2017 will be held at the Shenzhen Convention and Exhibition center! As the famous electronic manufacturing exhibition with great reputation in South China, NEPCON South China 2017 almost covers all of the electronic manufacturing industry chain, including EMS/OEM/ODM,consumer electronics, automotive electronics, computers, communications electronics and medical electronics, and other hot application fields.Unisplendour Suneast will bring the selective soldering machine, screen printer, and reflow oven, wave soldering machine, dispenser and BIMS system for showing in NEPCON South China 2017. Our booth no. is 1D65. Three high-end new products will be promoted, welcome to visit!

Exhibition Product

Selective soldering SUNFLOW DS

1、The independent R&D electromagnetic pump is easy to operate and maintenance, compared with other mechanical pumps, its wave is more stable, easy to control the wave height, and with good wave uniformity;

2、The spray nozzle of Suneast selective soldering machine adopts the imported special material, process with multiple processing,heat and surface treatment, which makes it’s not easy to be oxidized, has long service life, which service life of the single nozzle can prolong 30% times more than other nozzle in thesame industry;

3、Compared to the other selective soldering, Suneast soldering has vision alignment system for programming, accurate and fast;

4、The spray nozzle has auto cleaning function to prevent flux blockage.

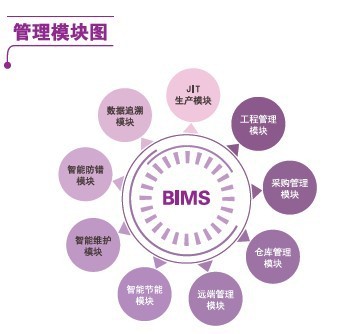

BIMS Intelligent Manufacturing Management System

For meeting the JIT (Just In Time) and BTO (build to order) and other new-type production mode, higher quality products required by the customer and market, Unisplendour Suneast BIMS system use the powerful data collection engine, cloud storage and cloud computing technology, which is an intelligent manufacturing system, and integrating the raw material supply, production planning, process control, product delivery, and customers tracing, total five functions. It can realize the information integration, transaction processing and intelligent manufacturing in different stages, and gives full play to the role of enterprise informatization, and establishes a solid foundation for enterprises to achieve industrial 4.0. It is the ultimate solution and leader of SMT line data information management and control.

Vertical Reflow Oven SVR-300

1、Compact structure, small space occupying, greatly saves building space;

2、High production efficiency which is much higher than the traditional oven, especially for the products which needs long time heating in the oven, effectively improves the production capacity and the solidification quality, and also reduce the usage cost;

3、Mainly apply forchip bonding, under fill, components packing and other production process which needs thermo curing.

Reflow Oven SER-708A Dual-rail

1、Low energy consumption:Through practical verification, compared with the peer, under the same speed and same temperature setting, and ensure the heat absorption difference between big or small size components is minimum, Suneast reflow oven can save 2KWH per hour than the peers;

2、Special width adjustment and conveyor structure design, ensure stable and reliable PCB conveying, adopts anti blocking chain;

3、Cooling system, brand new patented structure design, forced air cooling and water cooling structures can be upgraded and interchanged;

4、Modular structure, easy to clean, convenient and quick maintenance.

Screen printer T3 PLUS/H510

Suneast screen printer H510 won the 3rd section Industry Design“Red Sail Award”

1、 Suneast adopts the platform calibration algorithm which is better than the traditional mathematical model, to ensure high precision printing. Update the automatic calibration data after the warranty periodcan reset to the default value;

2、Suneast adopts the independent R&D and advanced visual positioning algorithm to ensure the high passing rate of the mark point recognition rate and the printing precision;

3、Suneast screen printer adopts the imported Ethernet digital camera which owns faster image processing speed, higher precision, wider vision, better video camera cable lines andquality;

4、Suneast adopts the suspended pressure detecting squeegee printing head and special printing scraper blade to ensure the printing quality; you can directly change the squeegee and the test the pressure, then itwill automatically do the calibration;

5、Suneast screen printer adopts open design, which is convenient for daily maintenance; when open the front and rear door, each any corner of the equipment can be reached;

6、Suneast screen printer owns built-in CPK detection function, you can test the recent precision at any time which is convenient for the customer tocheck the process requirements for printing machines.

Lead Free Wave Soldering Machine E-FLOW

1、The conveyor system adopts the brand new structure design, adopts the wear-resisting material which greatly enhances the service life of the rail.;

2、The preheating system adopts the drawer type module and energy-saving design, optimized micro hot air circulation path,even and stable temperature;

3、The spray system adopts precise regulating valve for digital regulation with convenient management, split design and easy maintenance;

4、The solder pot adopts external heating type,the solder pot liner is made of cast iron, the surface with anti-corrosion treatment, which can enhance its service life effectively.

Full Automatic Dispenser DP400H

1、Wide applications range: Suitable for most SMT products dispensing requirements and for kinds of glue;

2、Fast dispensing speed, UPH is during 7 million points, the repeatability accuracy is 0.01mm, and the positioning accuracy is less than 0.02mm;

3、Use the piezoelectric jet valve or pneumatic jet valve, fast, stable performance, simple operation, easy maintenance, and long service life;

4、Options: precision balance, on-line dispensing volumemonitoring; online conveyor system;can communicate with other devices.