2017-11-15

On November 1st, Guangdong Electronics Society unites with SMT Committee of Sichuan Electronics Society for holding 11th China high-end SMT academic conference in Mianyang city of Sichuan Province, and there were more than 200 participants.

The intelligent manufacturing is the core content of "China manufacturing 2025” which is also the trend of future development of the manufacturing industry, goes with the stream of the technological and the industrial revolution, and promotes the industry to high-end level. This conference is based on the previous discussion of electronic assembly technology, and focused on the intelligent manufacturing technology and the development direction of electronic assembly.

As the leading enterprise of the domestic SMT equipment manufacturer, Unisplendour Suneast Technology (Shenzhen)Co., Ltd.also plays an important role in overseas market that we was invited to attend this meeting. The general manager of Unisplendour Suneast Lin Xiaoxin attended this meeting, and shared Application of BIMS Intelligent Manufacturing Management System in Production Equipment.

What’s the Unisplendour Suneast BIMS Intelligent Manufacturing Management System?

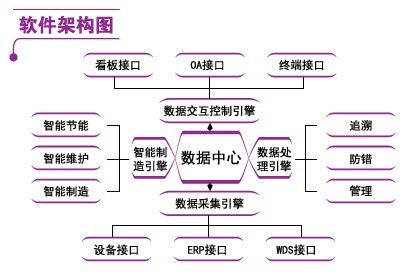

In order to meet the JIT (Just in Time), BTO (Build to Order) and other new-type production mode, the higher quality products requirement from the customer and market, Unisplendour Suneast BIMS system uses the data collection engine, cloud storage and cloud computing technology, which is an intelligent manufacturing system combines the raw material supply, production planning, process control, product delivery, and customers tracing, total five functions. It can realize the information integration, transaction processing and intelligent manufacturing in different stages, gives full play to the role of enterprise informatization, and establishes a solid foundation for enterprises to achieve industrial 4.0. It is the ultimate solution and leading technology of SMT line data information management and control.

What’s the features of Unisplendour Suneast BIMS Intelligent Manufacturing Management System?

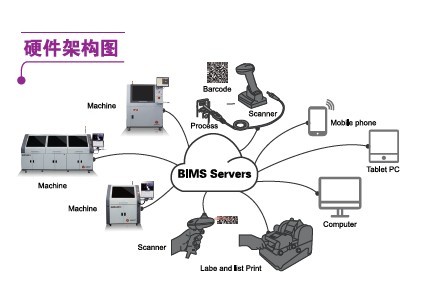

Seamless connection with the production equipment.Achieve seamless connection with the screen printer, dispenser, reflow oven, wave soldering, vertical oven and other equipment; automatically collect all the valuable data.

Super data acquisition capability from the third party.Full support to obtain data from 1D bar codes, 2D bar code, PLC, electronic scales, multimeter, Fluke meter, IO card, PID module and other information carrier or equipment, and use the industrial cameras and sensors to collect data from the equipment without data interface.

Data report and data mining.Automatically calculate the production efficiency, qualified rate, OEE and other key indicators at real time; automatically form the report, get the effective information from the collected data, make prejudge and suggestion combined with the analysis of massive data.

Powerful intelligent manufacturing capability.Intelligent scheduling, early warning, error proofing, energy conservation, maintenance, and diagnosis.

What’s the core management module of BIMS system?

BIMS system provides series of special managing tools and methods in modular way, which can refactor the production management system or the manufacturing execution system; with the self-developed rapid reconfiguration mechanism, and according to the customer business requirement, each module of the system can be assembled and depth customized flexibly, and add new features to make BIMS system has better ductility; according to the basic framework, BIMS system main functions include: JIT production, data tracing, intelligent error proofing, intelligent maintenance, intelligent energy saving, remote management, warehouse management, purchase management, engineering management; the actual customer system details will be customized according to customer needs, which has a deviations from the standard functional framework.

Target user of Unisplendour Suneast BIMS Intelligent Manufacturing Management System

Managers - Real time control the production status at anytime and anywhere:Real-time order progress schedule, OEE, production efficiency, product yield, and so on. Realize the order driving, Kanban management and pull production.

b. Technical personnel --- remote equipment control: active report of the state, automatic parameters switching, remote operation control …You can get reminders in advance, and control the operation of equipment at once.

Paperless, no error, zero inventory, no waste for the purpose, BIMS intelligent manufacturing management system aims to help enterprises to achieve a lower production cost, higher production efficiency, wider production range, less production people and faster marketing response speed.

After the meeting, the on-site customers talked with our General manager Lin Xiaoxin for further understanding about BIMS intelligent manufacturing management system. They focused on the application field, using effects, access device and other aspects about BIMS system. Our customers expressed high recognition and praise to the independent R&D intelligent manufacturing management system.